PDF Publication Title:

Text from PDF Page: 005

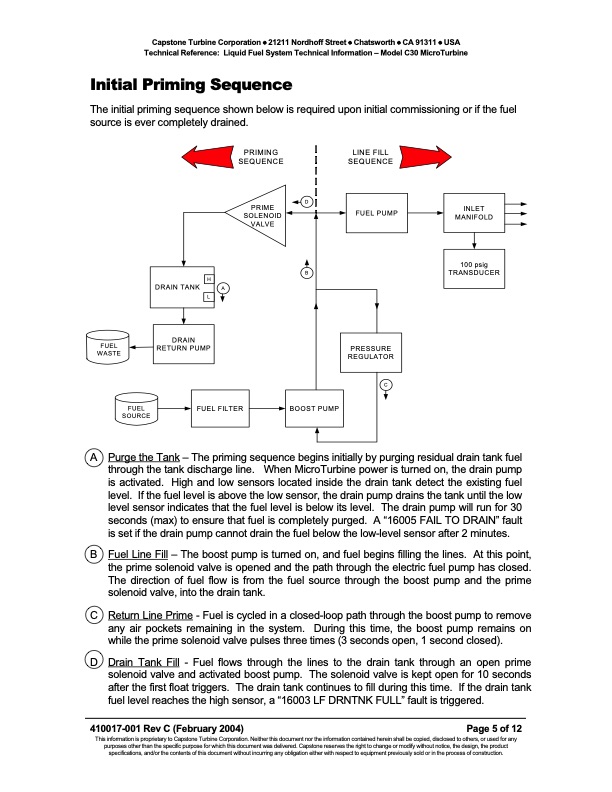

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: Liquid Fuel System Technical Information – Model C30 MicroTurbine Initial Priming Sequence The initial priming sequence shown below is required upon initial commissioning or if the fuel source is ever completely drained. PRIMING SEQUENCE PRIME SOLENOID VALVE LINE FILL SEQUENCE H DRAIN TANK L D B FUEL PUMP INLET MANIFOLD A 100 psig TRANSDUCER FUEL WASTE FUEL SOURCE C DRAIN RETURN PUMP PRESSURE REGULATOR FUEL FILTER BOOST PUMP A Purge the Tank – The priming sequence begins initially by purging residual drain tank fuel through the tank discharge line. When MicroTurbine power is turned on, the drain pump is activated. High and low sensors located inside the drain tank detect the existing fuel level. If the fuel level is above the low sensor, the drain pump drains the tank until the low level sensor indicates that the fuel level is below its level. The drain pump will run for 30 seconds (max) to ensure that fuel is completely purged. A “16005 FAIL TO DRAIN” fault is set if the drain pump cannot drain the fuel below the low-level sensor after 2 minutes. B Fuel Line Fill – The boost pump is turned on, and fuel begins filling the lines. At this point, the prime solenoid valve is opened and the path through the electric fuel pump has closed. The direction of fuel flow is from the fuel source through the boost pump and the prime solenoid valve, into the drain tank. C Return Line Prime - Fuel is cycled in a closed-loop path through the boost pump to remove any air pockets remaining in the system. During this time, the boost pump remains on while the prime solenoid valve pulses three times (3 seconds open, 1 second closed). D Drain Tank Fill - Fuel flows through the lines to the drain tank through an open prime solenoid valve and activated boost pump. The solenoid valve is kept open for 10 seconds after the first float triggers. The drain tank continues to fill during this time. If the drain tank fuel level reaches the high sensor, a “16003 LF DRNTNK FULL” fault is triggered. 410017-001 Rev C (February 2004) Page 5 of 12 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Technical Reference Liquid Fuel System Technical Information – Model C30 MicroTurbine

PDF Search Title:

Technical Reference Liquid Fuel System Technical Information – Model C30 MicroTurbineOriginal File Name Searched:

410017_ELOR_Tech_Ref.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |