PDF Publication Title:

Text from PDF Page: 004

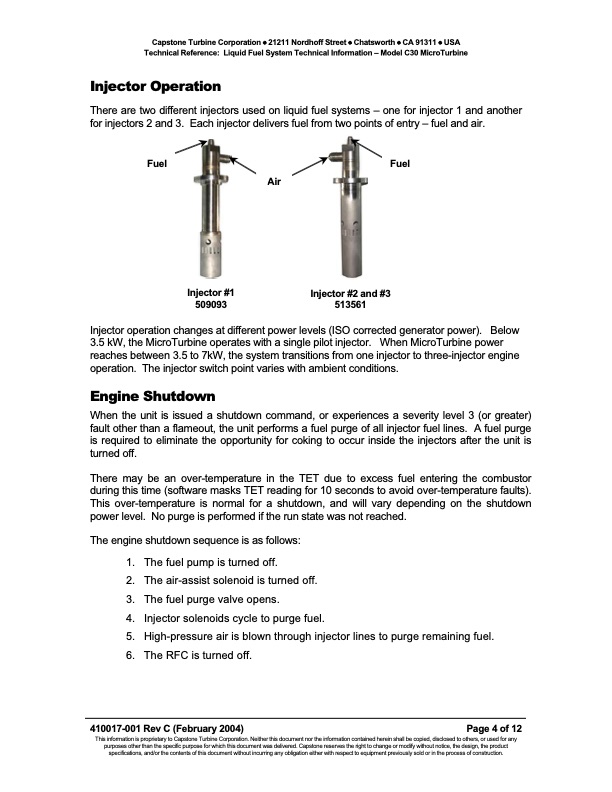

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: Liquid Fuel System Technical Information – Model C30 MicroTurbine Injector Operation There are two different injectors used on liquid fuel systems – one for injector 1 and another for injectors 2 and 3. Each injector delivers fuel from two points of entry – fuel and air. Fuel Fuel Air Injector #1 509093 Injector #2 and #3 513561 Injector operation changes at different power levels (ISO corrected generator power). Below 3.5 kW, the MicroTurbine operates with a single pilot injector. When MicroTurbine power reaches between 3.5 to 7kW, the system transitions from one injector to three-injector engine operation. The injector switch point varies with ambient conditions. Engine Shutdown When the unit is issued a shutdown command, or experiences a severity level 3 (or greater) fault other than a flameout, the unit performs a fuel purge of all injector fuel lines. A fuel purge is required to eliminate the opportunity for coking to occur inside the injectors after the unit is turned off. There may be an over-temperature in the TET due to excess fuel entering the combustor during this time (software masks TET reading for 10 seconds to avoid over-temperature faults). This over-temperature is normal for a shutdown, and will vary depending on the shutdown power level. No purge is performed if the run state was not reached. The engine shutdown sequence is as follows: 1. The fuel pump is turned off. 2. The air-assist solenoid is turned off. 3. The fuel purge valve opens. 4. Injector solenoids cycle to purge fuel. 5. High-pressure air is blown through injector lines to purge remaining fuel. 6. The RFC is turned off. 410017-001 Rev C (February 2004) Page 4 of 12 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Technical Reference Liquid Fuel System Technical Information – Model C30 MicroTurbine

PDF Search Title:

Technical Reference Liquid Fuel System Technical Information – Model C30 MicroTurbineOriginal File Name Searched:

410017_ELOR_Tech_Ref.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |