PDF Publication Title:

Text from PDF Page: 010

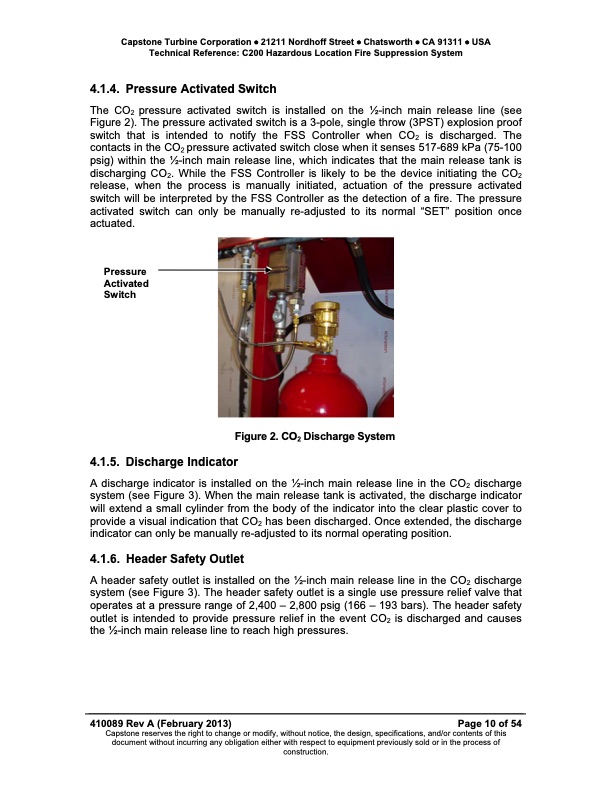

Capstone Turbine Corporation 21211 Nordhoff Street Chatsworth CA 91311 USA Technical Reference: C200 Hazardous Location Fire Suppression System 4.1.4. Pressure Activated Switch The CO2 pressure activated switch is installed on the 1⁄2-inch main release line (see Figure 2). The pressure activated switch is a 3-pole, single throw (3PST) explosion proof switch that is intended to notify the FSS Controller when CO2 is discharged. The contacts in the CO2 pressure activated switch close when it senses 517-689 kPa (75-100 psig) within the 1⁄2-inch main release line, which indicates that the main release tank is discharging CO2. While the FSS Controller is likely to be the device initiating the CO2 release, when the process is manually initiated, actuation of the pressure activated switch will be interpreted by the FSS Controller as the detection of a fire. The pressure activated switch can only be manually re-adjusted to its normal “SET” position once actuated. Pressure Activated Switch Figure 2. CO2 Discharge System 4.1.5. Discharge Indicator A discharge indicator is installed on the 1⁄2-inch main release line in the CO2 discharge system (see Figure 3). When the main release tank is activated, the discharge indicator will extend a small cylinder from the body of the indicator into the clear plastic cover to provide a visual indication that CO2 has been discharged. Once extended, the discharge indicator can only be manually re-adjusted to its normal operating position. 4.1.6. Header Safety Outlet A header safety outlet is installed on the 1⁄2-inch main release line in the CO2 discharge system (see Figure 3). The header safety outlet is a single use pressure relief valve that operates at a pressure range of 2,400 – 2,800 psig (166 – 193 bars). The header safety outlet is intended to provide pressure relief in the event CO2 is discharged and causes the 1⁄2-inch main release line to reach high pressures. 410089 Rev A (February 2013) Page 10 of 54 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Technical Reference C200 Hazloc Fire Suppression System

PDF Search Title:

Technical Reference C200 Hazloc Fire Suppression SystemOriginal File Name Searched:

410089A_TR_C200_HAZLOC_PKG_FIRE_SUPPRESSION_SYSTEM.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |