PDF Publication Title:

Text from PDF Page: 010

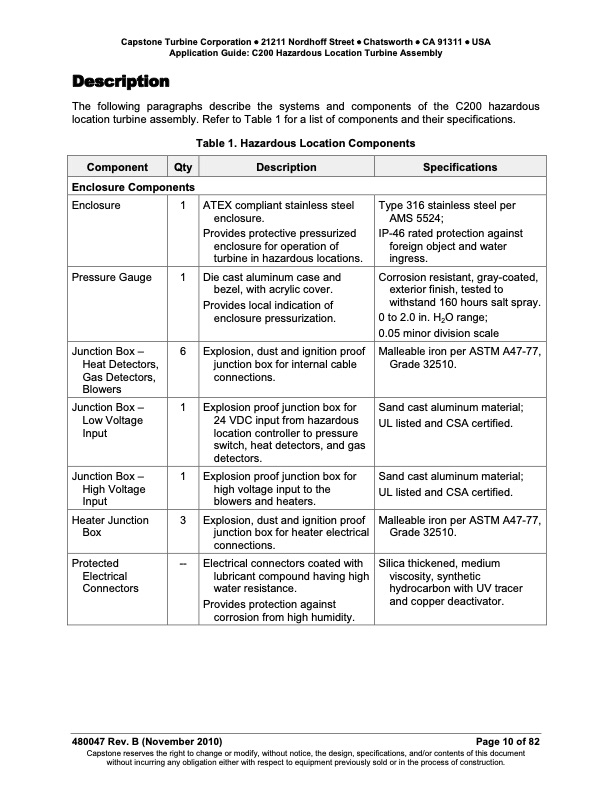

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Application Guide: C200 Hazardous Location Turbine Assembly Description The following paragraphs describe the systems and components of the C200 hazardous location turbine assembly. Refer to Table 1 for a list of components and their specifications. Table 1. Hazardous Location Components Enclosure Components Component Qty Description Specifications Enclosure 1 ATEX compliant stainless steel enclosure. Provides protective pressurized enclosure for operation of turbine in hazardous locations. Type 316 stainless steel per AMS 5524; IP-46 rated protection against foreign object and water ingress. Pressure Gauge 1 Die cast aluminum case and bezel, with acrylic cover. Provides local indication of enclosure pressurization. Corrosion resistant, gray-coated, exterior finish, tested to withstand 160 hours salt spray. 0 to 2.0 in. H2O range; 0.05 minor division scale Junction Box – Heat Detectors, Gas Detectors, Blowers 6 Explosion, dust and ignition proof junction box for internal cable connections. Malleable iron per ASTM A47-77, Grade 32510. Junction Box – Low Voltage Input 1 Explosion proof junction box for 24 VDC input from hazardous location controller to pressure switch, heat detectors, and gas detectors. Sand cast aluminum material; UL listed and CSA certified. Junction Box – High Voltage Input 1 Explosion proof junction box for high voltage input to the blowers and heaters. Sand cast aluminum material; UL listed and CSA certified. Heater Junction Box 3 Explosion, dust and ignition proof junction box for heater electrical connections. Malleable iron per ASTM A47-77, Grade 32510. Protected Electrical Connectors -- Electrical connectors coated with lubricant compound having high water resistance. Provides protection against corrosion from high humidity. Silica thickened, medium viscosity, synthetic hydrocarbon with UV tracer and copper deactivator. 480047 Rev. B (November 2010) Page 10 of 82 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Application Guide Capstone Model C200 Hazardous Location Turbine Assembly

PDF Search Title:

Application Guide Capstone Model C200 Hazardous Location Turbine AssemblyOriginal File Name Searched:

480047B_C200_Hazloc_Package_AG.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |