PDF Publication Title:

Text from PDF Page: 026

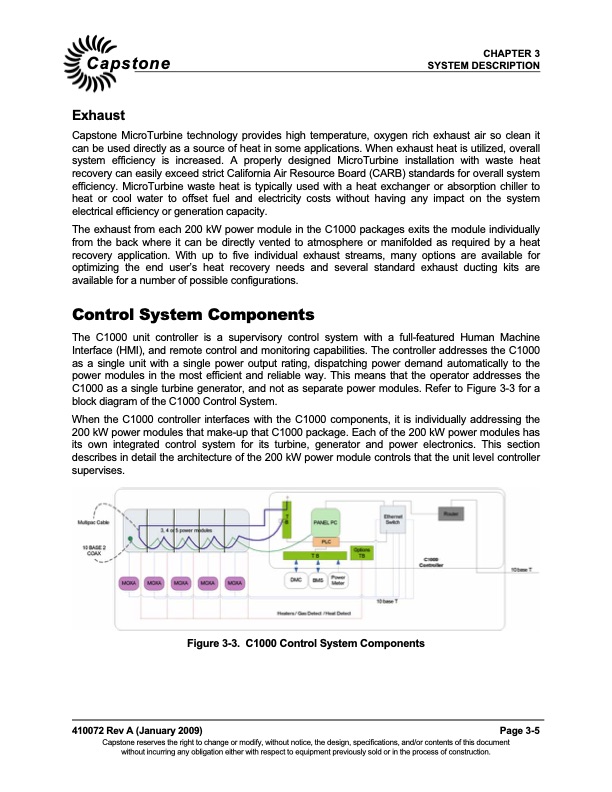

CHAPTER 3 Capstone SYSTEM DESCRIPTION Exhaust Capstone MicroTurbine technology provides high temperature, oxygen rich exhaust air so clean it can be used directly as a source of heat in some applications. When exhaust heat is utilized, overall system efficiency is increased. A properly designed MicroTurbine installation with waste heat recovery can easily exceed strict California Air Resource Board (CARB) standards for overall system efficiency. MicroTurbine waste heat is typically used with a heat exchanger or absorption chiller to heat or cool water to offset fuel and electricity costs without having any impact on the system electrical efficiency or generation capacity. The exhaust from each 200 kW power module in the C1000 packages exits the module individually from the back where it can be directly vented to atmosphere or manifolded as required by a heat recovery application. With up to five individual exhaust streams, many options are available for optimizing the end user’s heat recovery needs and several standard exhaust ducting kits are available for a number of possible configurations. Control System Components The C1000 unit controller is a supervisory control system with a full-featured Human Machine Interface (HMI), and remote control and monitoring capabilities. The controller addresses the C1000 as a single unit with a single power output rating, dispatching power demand automatically to the power modules in the most efficient and reliable way. This means that the operator addresses the C1000 as a single turbine generator, and not as separate power modules. Refer to Figure 3-3 for a block diagram of the C1000 Control System. When the C1000 controller interfaces with the C1000 components, it is individually addressing the 200 kW power modules that make-up that C1000 package. Each of the 200 kW power modules has its own integrated control system for its turbine, generator and power electronics. This section describes in detail the architecture of the 200 kW power module controls that the unit level controller supervises. Figure 3-3. C1000 Control System Components 410072 Rev A (January 2009) Page 3-5 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | CAPSTONE C1000 MICROTURBINE SYSTEMS TECHNICAL REFERENCE

PDF Search Title:

CAPSTONE C1000 MICROTURBINE SYSTEMS TECHNICAL REFERENCEOriginal File Name Searched:

410072A_C1000_TR.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |