PDF Publication Title:

Text from PDF Page: 025

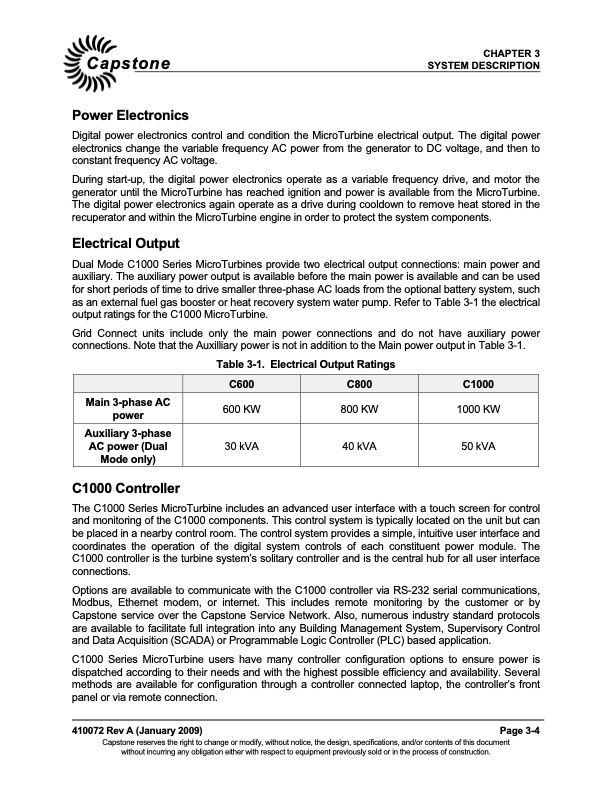

CHAPTER 3 Capstone SYSTEM DESCRIPTION Power Electronics Digital power electronics control and condition the MicroTurbine electrical output. The digital power electronics change the variable frequency AC power from the generator to DC voltage, and then to constant frequency AC voltage. During start-up, the digital power electronics operate as a variable frequency drive, and motor the generator until the MicroTurbine has reached ignition and power is available from the MicroTurbine. The digital power electronics again operate as a drive during cooldown to remove heat stored in the recuperator and within the MicroTurbine engine in order to protect the system components. Electrical Output Dual Mode C1000 Series MicroTurbines provide two electrical output connections: main power and auxiliary. The auxiliary power output is available before the main power is available and can be used for short periods of time to drive smaller three-phase AC loads from the optional battery system, such as an external fuel gas booster or heat recovery system water pump. Refer to Table 3-1 the electrical output ratings for the C1000 MicroTurbine. Grid Connect units include only the main power connections and do not have auxiliary power connections. Note that the Auxilliary power is not in addition to the Main power output in Table 3-1. C600 C800 C1000 Main 3-phase AC power C1000 Controller Table 3-1. Electrical Output Ratings 600 KW 800 KW 1000 KW Auxiliary 3-phase AC power (Dual Mode only) 30 kVA 40 kVA 50 kVA The C1000 Series MicroTurbine includes an advanced user interface with a touch screen for control and monitoring of the C1000 components. This control system is typically located on the unit but can be placed in a nearby control room. The control system provides a simple, intuitive user interface and coordinates the operation of the digital system controls of each constituent power module. The C1000 controller is the turbine system’s solitary controller and is the central hub for all user interface connections. Options are available to communicate with the C1000 controller via RS-232 serial communications, Modbus, Ethernet modem, or internet. This includes remote monitoring by the customer or by Capstone service over the Capstone Service Network. Also, numerous industry standard protocols are available to facilitate full integration into any Building Management System, Supervisory Control and Data Acquisition (SCADA) or Programmable Logic Controller (PLC) based application. C1000 Series MicroTurbine users have many controller configuration options to ensure power is dispatched according to their needs and with the highest possible efficiency and availability. Several methods are available for configuration through a controller connected laptop, the controller’s front panel or via remote connection. 410072 Rev A (January 2009) Page 3-4 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | CAPSTONE C1000 MICROTURBINE SYSTEMS TECHNICAL REFERENCE

PDF Search Title:

CAPSTONE C1000 MICROTURBINE SYSTEMS TECHNICAL REFERENCEOriginal File Name Searched:

410072A_C1000_TR.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |