PDF Publication Title:

Text from PDF Page: 074

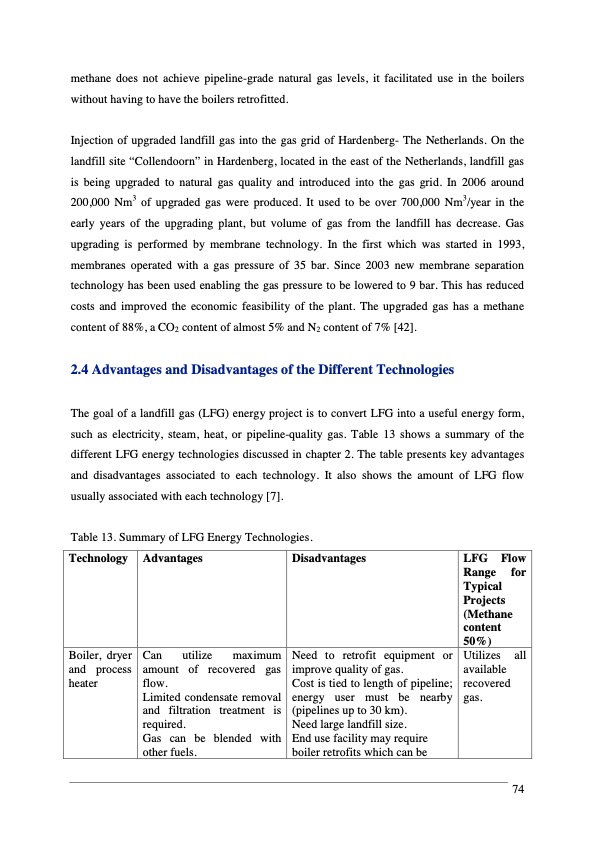

methane does not achieve pipeline-grade natural gas levels, it facilitated use in the boilers without having to have the boilers retrofitted. Injection of upgraded landfill gas into the gas grid of Hardenberg- The Netherlands. On the landfill site “Collendoorn” in Hardenberg, located in the east of the Netherlands, landfill gas is being upgraded to natural gas quality and introduced into the gas grid. In 2006 around 33 200,000 Nm of upgraded gas were produced. It used to be over 700,000 Nm /year in the early years of the upgrading plant, but volume of gas from the landfill has decrease. Gas upgrading is performed by membrane technology. In the first which was started in 1993, membranes operated with a gas pressure of 35 bar. Since 2003 new membrane separation technology has been used enabling the gas pressure to be lowered to 9 bar. This has reduced costs and improved the economic feasibility of the plant. The upgraded gas has a methane content of 88%, a CO2 content of almost 5% and N2 content of 7% [42]. 2.4 Advantages and Disadvantages of the Different Technologies The goal of a landfill gas (LFG) energy project is to convert LFG into a useful energy form, such as electricity, steam, heat, or pipeline-quality gas. Table 13 shows a summary of the different LFG energy technologies discussed in chapter 2. The table presents key advantages and disadvantages associated to each technology. It also shows the amount of LFG flow usually associated with each technology [7]. Table 13. Summary of LFG Energy Technologies. T echnology Advantages Disadvantages LFG Flow Range for Typical Projects (Methane content 50%) Boiler, dryer and process heater Can utilize maximum amount of recovered gas flow. Limited condensate removal and filtration treatment is required. Gas can be blended with other fuels. Need to retrofit equipment or improve quality of gas. Cost is tied to length of pipeline; energy user must be nearby (pipelines up to 30 km). Need large landfill size. End use facility may require boiler retrofits which can be Utilizes all available recovered gas. 74PDF Image | Landfill Gas Energy Technologies

PDF Search Title:

Landfill Gas Energy TechnologiesOriginal File Name Searched:

1022_LFG-Handbook.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |