PDF Publication Title:

Text from PDF Page: 041

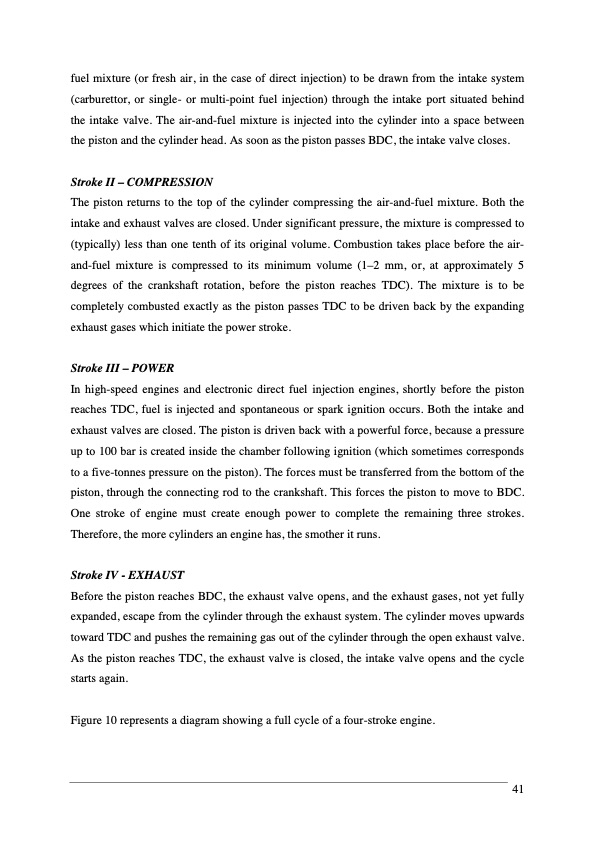

fuel mixture (or fresh air, in the case of direct injection) to be drawn from the intake system (carburettor, or single- or multi-point fuel injection) through the intake port situated behind the intake valve. The air-and-fuel mixture is injected into the cylinder into a space between the piston and the cylinder head. As soon as the piston passes BDC, the intake valve closes. Stroke II – COMPRESSION The piston returns to the top of the cylinder compressing the air-and-fuel mixture. Both the intake and exhaust valves are closed. Under significant pressure, the mixture is compressed to (typically) less than one tenth of its original volume. Combustion takes place before the air- and-fuel mixture is compressed to its minimum volume (1–2 mm, or, at approximately 5 degrees of the crankshaft rotation, before the piston reaches TDC). The mixture is to be completely combusted exactly as the piston passes TDC to be driven back by the expanding exhaust gases which initiate the power stroke. Stroke III – POWER In high-speed engines and electronic direct fuel injection engines, shortly before the piston reaches TDC, fuel is injected and spontaneous or spark ignition occurs. Both the intake and exhaust valves are closed. The piston is driven back with a powerful force, because a pressure up to 100 bar is created inside the chamber following ignition (which sometimes corresponds to a five-tonnes pressure on the piston). The forces must be transferred from the bottom of the piston, through the connecting rod to the crankshaft. This forces the piston to move to BDC. One stroke of engine must create enough power to complete the remaining three strokes. Therefore, the more cylinders an engine has, the smother it runs. Stroke IV - EXHAUST Before the piston reaches BDC, the exhaust valve opens, and the exhaust gases, not yet fully expanded, escape from the cylinder through the exhaust system. The cylinder moves upwards toward TDC and pushes the remaining gas out of the cylinder through the open exhaust valve. As the piston reaches TDC, the exhaust valve is closed, the intake valve opens and the cycle starts again. Figure 10 represents a diagram showing a full cycle of a four-stroke engine. 41PDF Image | Landfill Gas Energy Technologies

PDF Search Title:

Landfill Gas Energy TechnologiesOriginal File Name Searched:

1022_LFG-Handbook.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |