PDF Publication Title:

Text from PDF Page: 047

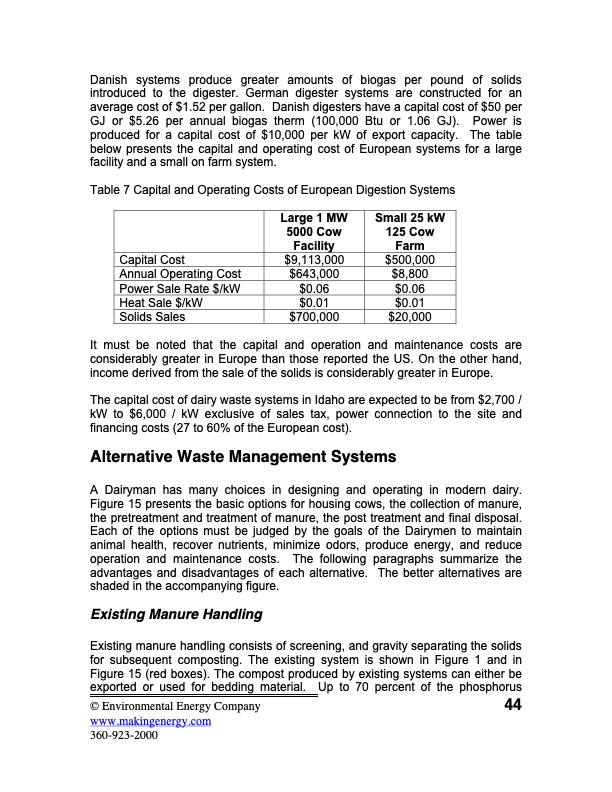

Danish systems produce greater amounts of biogas per pound of solids introduced to the digester. German digester systems are constructed for an average cost of $1.52 per gallon. Danish digesters have a capital cost of $50 per GJ or $5.26 per annual biogas therm (100,000 Btu or 1.06 GJ). Power is produced for a capital cost of $10,000 per kW of export capacity. The table below presents the capital and operating cost of European systems for a large facility and a small on farm system. Table 7 Capital and Operating Costs of European Digestion Systems Large 1 MW 5000 Cow Facility Small 25 kW 125 Cow Farm Capital Cost Annual Operating Cost Power Sale Rate $/kW Heat Sale $/kW Solids Sales $9,113,000 $643,000 $0.06 $0.01 $700,000 $500,000 $8,800 $0.06 $0.01 $20,000 It must be noted that the capital and operation and maintenance costs are considerably greater in Europe than those reported the US. On the other hand, income derived from the sale of the solids is considerably greater in Europe. The capital cost of dairy waste systems in Idaho are expected to be from $2,700 / kW to $6,000 / kW exclusive of sales tax, power connection to the site and financing costs (27 to 60% of the European cost). Alternative Waste Management Systems A Dairyman has many choices in designing and operating in modern dairy. Figure 15 presents the basic options for housing cows, the collection of manure, the pretreatment and treatment of manure, the post treatment and final disposal. Each of the options must be judged by the goals of the Dairymen to maintain animal health, recover nutrients, minimize odors, produce energy, and reduce operation and maintenance costs. The following paragraphs summarize the advantages and disadvantages of each alternative. The better alternatives are shaded in the accompanying figure. Existing Manure Handling Existing manure handling consists of screening, and gravity separating the solids for subsequent composting. The existing system is shown in Figure 1 and in Figure 15 (red boxes). The compost produced by existing systems can either be exported or used for bedding material. Up to 70 percent of the phosphorus © Environmental Energy Company 44 www.makingenergy.com 360-923-2000PDF Image | Dairy Waste Anaerobic Digestion Handbook Options for Recovering Beneficial Products From Dairy Manure

PDF Search Title:

Dairy Waste Anaerobic Digestion Handbook Options for Recovering Beneficial Products From Dairy ManureOriginal File Name Searched:

biogas11.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |