PDF Publication Title:

Text from PDF Page: 046

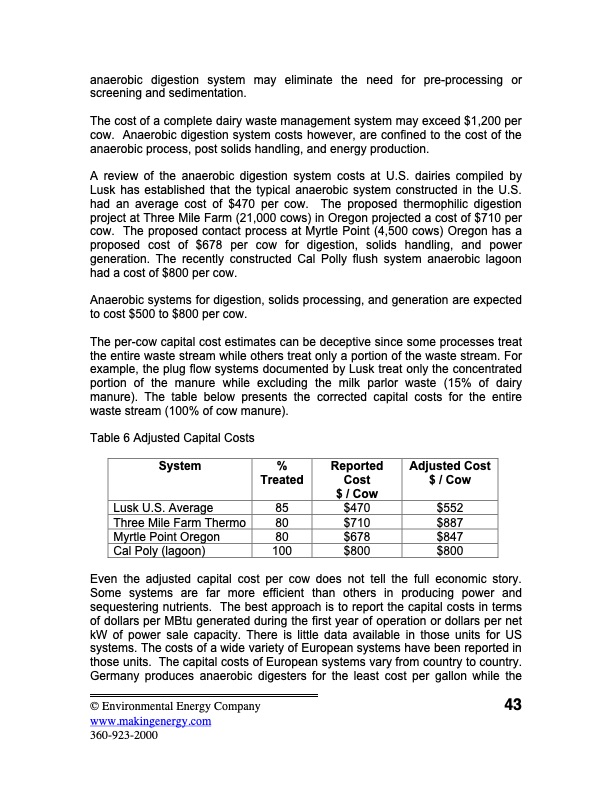

anaerobic digestion system may eliminate the need for pre-processing or screening and sedimentation. The cost of a complete dairy waste management system may exceed $1,200 per cow. Anaerobic digestion system costs however, are confined to the cost of the anaerobic process, post solids handling, and energy production. A review of the anaerobic digestion system costs at U.S. dairies compiled by Lusk has established that the typical anaerobic system constructed in the U.S. had an average cost of $470 per cow. The proposed thermophilic digestion project at Three Mile Farm (21,000 cows) in Oregon projected a cost of $710 per cow. The proposed contact process at Myrtle Point (4,500 cows) Oregon has a proposed cost of $678 per cow for digestion, solids handling, and power generation. The recently constructed Cal Polly flush system anaerobic lagoon had a cost of $800 per cow. Anaerobic systems for digestion, solids processing, and generation are expected to cost $500 to $800 per cow. The per-cow capital cost estimates can be deceptive since some processes treat the entire waste stream while others treat only a portion of the waste stream. For example, the plug flow systems documented by Lusk treat only the concentrated portion of the manure while excluding the milk parlor waste (15% of dairy manure). The table below presents the corrected capital costs for the entire waste stream (100% of cow manure). Table 6 Adjusted Capital Costs Lusk U.S. Average 85 $470 $552 Three Mile Farm Thermo 80 $710 $887 Myrtle Point Oregon 80 $678 $847 Cal Poly (lagoon) 100 $800 $800 Even the adjusted capital cost per cow does not tell the full economic story. Some systems are far more efficient than others in producing power and sequestering nutrients. The best approach is to report the capital costs in terms of dollars per MBtu generated during the first year of operation or dollars per net kW of power sale capacity. There is little data available in those units for US systems. The costs of a wide variety of European systems have been reported in those units. The capital costs of European systems vary from country to country. Germany produces anaerobic digesters for the least cost per gallon while the © Environmental Energy Company 43 www.makingenergy.com 360-923-2000 System % Treated Reported Cost $ / Cow Adjusted Cost $ / CowPDF Image | Dairy Waste Anaerobic Digestion Handbook Options for Recovering Beneficial Products From Dairy Manure

PDF Search Title:

Dairy Waste Anaerobic Digestion Handbook Options for Recovering Beneficial Products From Dairy ManureOriginal File Name Searched:

biogas11.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |