PDF Publication Title:

Text from PDF Page: 076

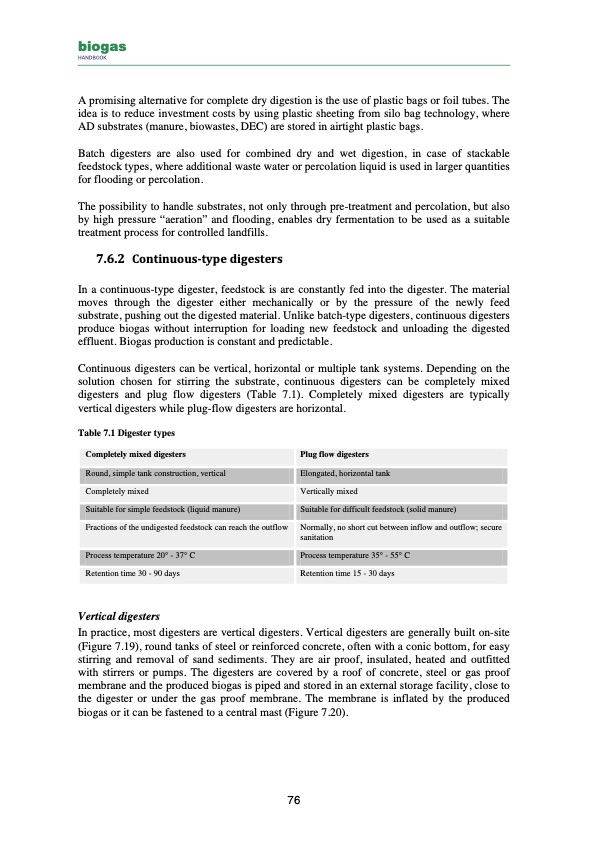

biogas HANDBOOK A promising alternative for complete dry digestion is the use of plastic bags or foil tubes. The idea is to reduce investment costs by using plastic sheeting from silo bag technology, where AD substrates (manure, biowastes, DEC) are stored in airtight plastic bags. Batch digesters are also used for combined dry and wet digestion, in case of stackable feedstock types, where additional waste water or percolation liquid is used in larger quantities for flooding or percolation. The possibility to handle substrates, not only through pre-treatment and percolation, but also by high pressure “aeration” and flooding, enables dry fermentation to be used as a suitable treatment process for controlled landfills. 7.6.2 Continuous-typedigesters In a continuous-type digester, feedstock is are constantly fed into the digester. The material moves through the digester either mechanically or by the pressure of the newly feed substrate, pushing out the digested material. Unlike batch-type digesters, continuous digesters produce biogas without interruption for loading new feedstock and unloading the digested effluent. Biogas production is constant and predictable. Continuous digesters can be vertical, horizontal or multiple tank systems. Depending on the solution chosen for stirring the substrate, continuous digesters can be completely mixed digesters and plug flow digesters (Table 7.1). Completely mixed digesters are typically vertical digesters while plug-flow digesters are horizontal. Table 7.1 Digester types Completely mixed digesters Plug flow digesters Round, simple tank construction, vertical Elongated, horizontal tank Completely mixed Vertically mixed Suitable for simple feedstock (liquid manure) Suitable for difficult feedstock (solid manure) Fractions of the undigested feedstock can reach the outflow Normally, no short cut between inflow and outflow; secure sanitation Process temperature 20° - 37° C Process temperature 35° - 55° C Retention time 30 - 90 days Retention time 15 - 30 days Vertical digesters In practice, most digesters are vertical digesters. Vertical digesters are generally built on-site (Figure 7.19), round tanks of steel or reinforced concrete, often with a conic bottom, for easy stirring and removal of sand sediments. They are air proof, insulated, heated and outfitted with stirrers or pumps. The digesters are covered by a roof of concrete, steel or gas proof membrane and the produced biogas is piped and stored in an external storage facility, close to the digester or under the gas proof membrane. The membrane is inflated by the produced biogas or it can be fastened to a central mast (Figure 7.20). 76PDF Image | biogas HANDBOOK

PDF Search Title:

biogas HANDBOOKOriginal File Name Searched:

BiogasHandbook.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |