PDF Publication Title:

Text from PDF Page: 042

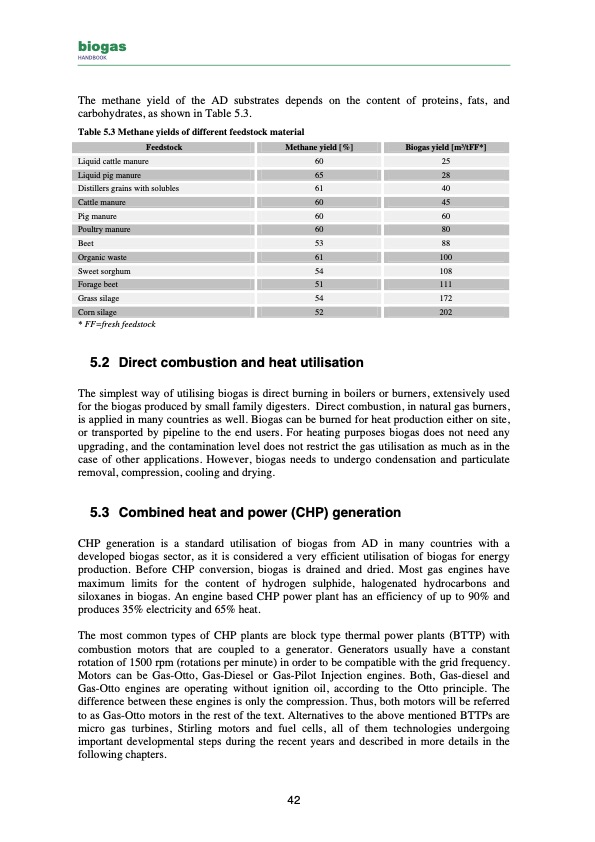

biogas HANDBOOK The methane yield of the AD substrates depends on the content of proteins, fats, and carbohydrates, as shown in Table 5.3. Table 5.3 Methane yields of different feedstock material Feedstock Methane yield [%] Biogas yield [m3/tFF*] Liquid cattle manure 60 25 Liquid pig manure 65 28 Distillers grains with solubles 61 40 Cattle manure 60 45 Pig manure 60 60 Poultry manure 60 80 Beet 53 88 Organic waste 61 100 Sweet sorghum 54 108 Forage beet 51 111 Grass silage 54 172 Corn silage 52 202 * FF=fresh feedstock 5.2 Directcombustionandheatutilisation The simplest way of utilising biogas is direct burning in boilers or burners, extensively used for the biogas produced by small family digesters. Direct combustion, in natural gas burners, is applied in many countries as well. Biogas can be burned for heat production either on site, or transported by pipeline to the end users. For heating purposes biogas does not need any upgrading, and the contamination level does not restrict the gas utilisation as much as in the case of other applications. However, biogas needs to undergo condensation and particulate removal, compression, cooling and drying. 5.3 Combinedheatandpower(CHP)generation CHP generation is a standard utilisation of biogas from AD in many countries with a developed biogas sector, as it is considered a very efficient utilisation of biogas for energy production. Before CHP conversion, biogas is drained and dried. Most gas engines have maximum limits for the content of hydrogen sulphide, halogenated hydrocarbons and siloxanes in biogas. An engine based CHP power plant has an efficiency of up to 90% and produces 35% electricity and 65% heat. The most common types of CHP plants are block type thermal power plants (BTTP) with combustion motors that are coupled to a generator. Generators usually have a constant rotation of 1500 rpm (rotations per minute) in order to be compatible with the grid frequency. Motors can be Gas-Otto, Gas-Diesel or Gas-Pilot Injection engines. Both, Gas-diesel and Gas-Otto engines are operating without ignition oil, according to the Otto principle. The difference between these engines is only the compression. Thus, both motors will be referred to as Gas-Otto motors in the rest of the text. Alternatives to the above mentioned BTTPs are micro gas turbines, Stirling motors and fuel cells, all of them technologies undergoing important developmental steps during the recent years and described in more details in the following chapters. 42PDF Image | biogas HANDBOOK

PDF Search Title:

biogas HANDBOOKOriginal File Name Searched:

BiogasHandbook.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |