PDF Publication Title:

Text from PDF Page: 023

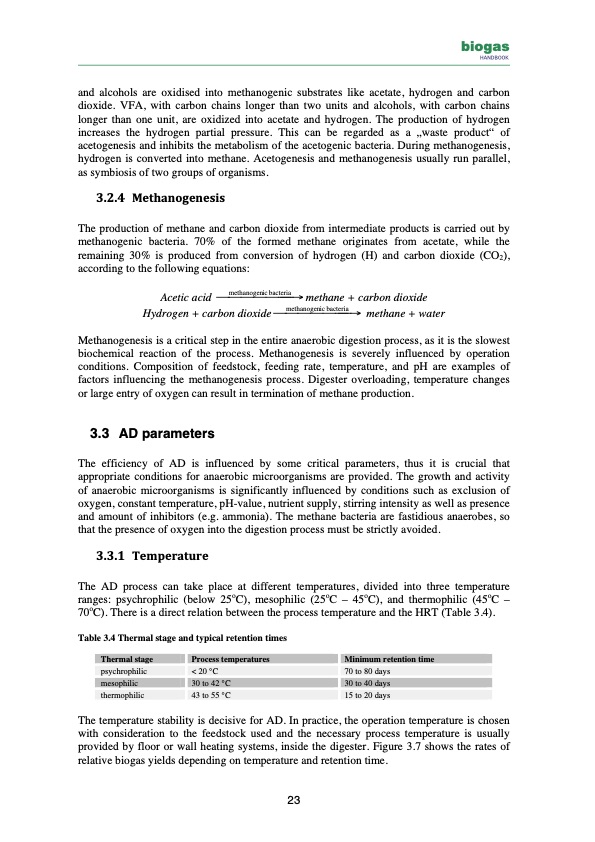

biogas HANDBOOK and alcohols are oxidised into methanogenic substrates like acetate, hydrogen and carbon dioxide. VFA, with carbon chains longer than two units and alcohols, with carbon chains longer than one unit, are oxidized into acetate and hydrogen. The production of hydrogen increases the hydrogen partial pressure. This can be regarded as a „waste product“ of acetogenesis and inhibits the metabolism of the acetogenic bacteria. During methanogenesis, hydrogen is converted into methane. Acetogenesis and methanogenesis usually run parallel, as symbiosis of two groups of organisms. 3.2.4 Methanogenesis The production of methane and carbon dioxide from intermediate products is carried out by methanogenic bacteria. 70% of the formed methane originates from acetate, while the remaining 30% is produced from conversion of hydrogen (H) and carbon dioxide (CO2), according to the following equations: Acetic acid → methane + carbon dioxide methanogenic bacteria methanogenic bacteria Hydrogen + carbon dioxide → methane + water Methanogenesis is a critical step in the entire anaerobic digestion process, as it is the slowest biochemical reaction of the process. Methanogenesis is severely influenced by operation conditions. Composition of feedstock, feeding rate, temperature, and pH are examples of factors influencing the methanogenesis process. Digester overloading, temperature changes or large entry of oxygen can result in termination of methane production. 3.3 ADparameters The efficiency of AD is influenced by some critical parameters, thus it is crucial that appropriate conditions for anaerobic microorganisms are provided. The growth and activity of anaerobic microorganisms is significantly influenced by conditions such as exclusion of oxygen, constant temperature, pH-value, nutrient supply, stirring intensity as well as presence and amount of inhibitors (e.g. ammonia). The methane bacteria are fastidious anaerobes, so that the presence of oxygen into the digestion process must be strictly avoided. 3.3.1 Temperature The AD process can take place at different temperatures, divided into three temperature oooo ranges: psychrophilic (below 25 C), mesophilic (25 C – 45 C), and thermophilic (45 C – o 70 C). There is a direct relation between the process temperature and the HRT (Table 3.4). Table 3.4 Thermal stage and typical retention times The temperature stability is decisive for AD. In practice, the operation temperature is chosen with consideration to the feedstock used and the necessary process temperature is usually provided by floor or wall heating systems, inside the digester. Figure 3.7 shows the rates of relative biogas yields depending on temperature and retention time. Thermal stage Process temperatures Minimum retention time psychrophilic < 20 °C 70 to 80 days mesophilic 30 to 42 °C 30 to 40 days thermophilic 43 to 55 °C 15 to 20 days 23PDF Image | biogas HANDBOOK

PDF Search Title:

biogas HANDBOOKOriginal File Name Searched:

BiogasHandbook.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |