PDF Publication Title:

Text from PDF Page: 013

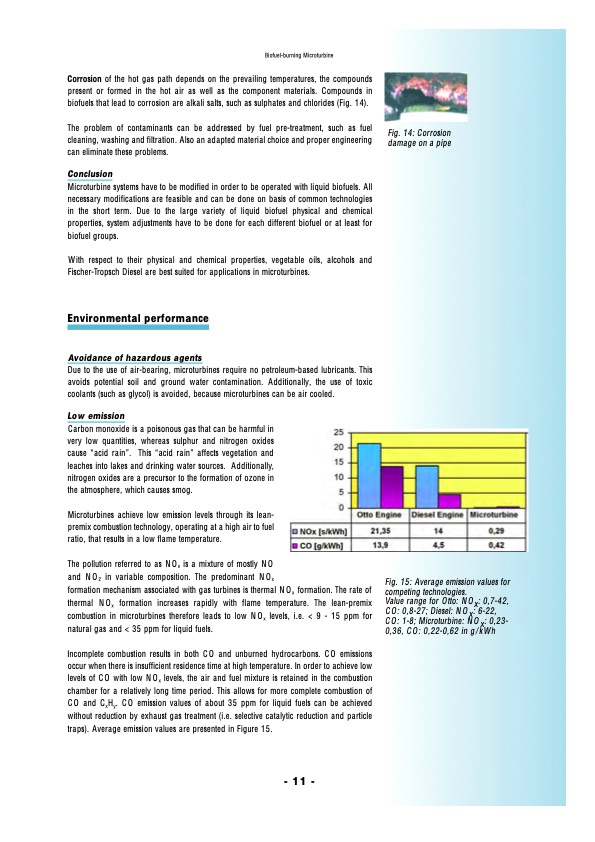

Corrosion of the hot gas path depends on the prevailing temperatures, the compounds present or formed in the hot air as well as the component materials. Compounds in biofuels that lead to corrosion are alkali salts, such as sulphates and chlorides (Fig. 14). The problem of contaminants can be addressed by fuel pre-treatment, such as fuel cleaning, washing and filtration. Also an adapted material choice and proper engineering can eliminate these problems. Conclusion Microturbine systems have to be modified in order to be operated with liquid biofuels. All necessary modifications are feasible and can be done on basis of common technologies in the short term. Due to the large variety of liquid biofuel physical and chemical properties, system adjustments have to be done for each different biofuel or at least for biofuel groups. With respect to their physical and chemical properties, vegetable oils, alcohols and Fischer-Tropsch Diesel are best suited for applications in microturbines. Environmental performance Avoidance of hazardous agents Due to the use of air-bearing, microturbines require no petroleum-based lubricants. This avoids potential soil and ground water contamination. Additionally, the use of toxic coolants (such as glycol) is avoided, because microturbines can be air cooled. Low emission Carbon monoxide is a poisonous gas that can be harmful in very low quantities, whereas sulphur and nitrogen oxides cause “acid rain”. This “acid rain” affects vegetation and leaches into lakes and drinking water sources. Additionally, nitrogen oxides are a precursor to the formation of ozone in the atmosphere, which causes smog. Microturbines achieve low emission levels through its lean- premix combustion technology, operating at a high air to fuel ratio, that results in a low flame temperature. The pollution referred to as NOx is a mixture of mostly NO and NO2 in variable composition. The predominant NOx formation mechanism associated with gas turbines is thermal NOx formation. The rate of thermal NOx formation increases rapidly with flame temperature. The lean-premix combustion in microturbines therefore leads to low NOx levels, i.e. < 9 - 15 ppm for natural gas and < 35 ppm for liquid fuels. Incomplete combustion results in both CO and unburned hydrocarbons. CO emissions occur when there is insufficient residence time at high temperature. In order to achieve low levels of CO with low NOx levels, the air and fuel mixture is retained in the combustion chamber for a relatively long time period. This allows for more complete combustion of CO and CxHy. CO emission values of about 35 ppm for liquid fuels can be achieved without reduction by exhaust gas treatment (i.e. selective catalytic reduction and particle traps). Average emission values are presented in Figure 15. Fig. 14: Corrosion damage on a pipe Biofuel-burning Microturbine - 11 - Fig. 15: Average emission values for competing technologies. Value range for Otto: NOx: 0,7-42, CO: 0,8-27; Diesel: NOx: 6-22, CO: 1-8; Microturbine: NOx: 0,23- 0,36, CO: 0,22-0,62 in g/kWhPDF Image | Biofuel-burning Microturbine Opportunities for Biofuel-burning Microturbines in the European Decentralised-generation Market (BIOTURBINE)

PDF Search Title:

Biofuel-burning Microturbine Opportunities for Biofuel-burning Microturbines in the European Decentralised-generation Market (BIOTURBINE)Original File Name Searched:

Bioturbine_brochure.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |