PDF Publication Title:

Text from PDF Page: 059

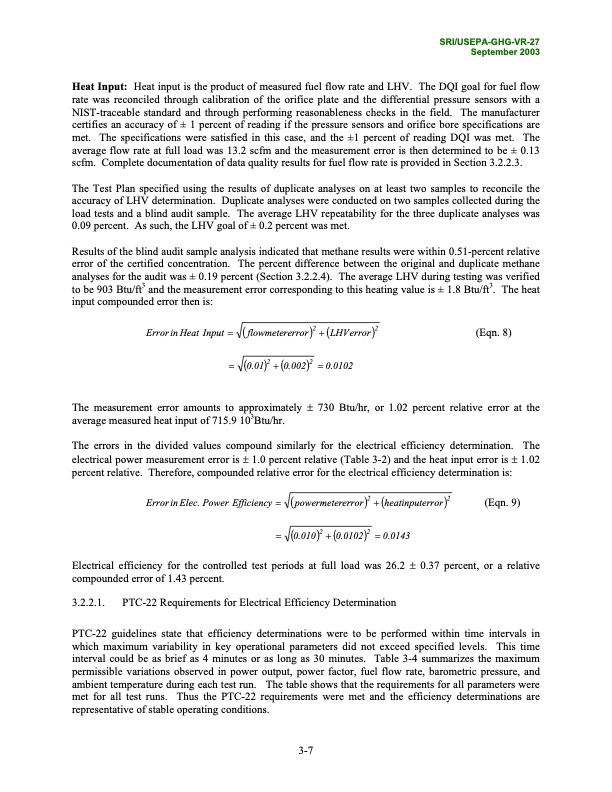

SRI/USEPA-GHG-VR-27 September 2003 Heat Input: Heat input is the product of measured fuel flow rate and LHV. The DQI goal for fuel flow rate was reconciled through calibration of the orifice plate and the differential pressure sensors with a NIST-traceable standard and through performing reasonableness checks in the field. The manufacturer certifies an accuracy of ± 1 percent of reading if the pressure sensors and orifice bore specifications are met. The specifications were satisfied in this case, and the ±1 percent of reading DQI was met. The average flow rate at full load was 13.2 scfm and the measurement error is then determined to be ± 0.13 scfm. Complete documentation of data quality results for fuel flow rate is provided in Section 3.2.2.3. The Test Plan specified using the results of duplicate analyses on at least two samples to reconcile the accuracy of LHV determination. Duplicate analyses were conducted on two samples collected during the load tests and a blind audit sample. The average LHV repeatability for the three duplicate analyses was 0.09 percent. As such, the LHV goal of ± 0.2 percent was met. Results of the blind audit sample analysis indicated that methane results were within 0.51-percent relative error of the certified concentration. The percent difference between the original and duplicate methane analyses for the audit was ± 0.19 percent (Section 3.2.2.4). The average LHV during testing was verified to be 903 Btu/ft3 and the measurement error corresponding to this heating value is ± 1.8 Btu/ft3. The heat input compounded error then is: 22 Error in Heat Input = ( flowmetererror ) + (LHV error ) (Eqn. 8) = (0.01)2 + (0.002)2 = 0.0102 The measurement error amounts to approximately ± 730 Btu/hr, or 1.02 percent relative error at the average measured heat input of 715.9 103Btu/hr. The errors in the divided values compound similarly for the electrical efficiency determination. The electrical power measurement error is ± 1.0 percent relative (Table 3-2) and the heat input error is ± 1.02 percent relative. Therefore, compounded relative error for the electrical efficiency determination is: 22 ErrorinElec.Power Efficiency= (powermetererror) +(heatinputerror) (Eqn.9) 22 = (0.010) +(0.0102) =0.0143 Electrical efficiency for the controlled test periods at full load was 26.2 ± 0.37 percent, or a relative compounded error of 1.43 percent. 3.2.2.1. PTC-22 Requirements for Electrical Efficiency Determination PTC-22 guidelines state that efficiency determinations were to be performed within time intervals in which maximum variability in key operational parameters did not exceed specified levels. This time interval could be as brief as 4 minutes or as long as 30 minutes. Table 3-4 summarizes the maximum permissible variations observed in power output, power factor, fuel flow rate, barometric pressure, and ambient temperature during each test run. The table shows that the requirements for all parameters were met for all test runs. Thus the PTC-22 requirements were met and the efficiency determinations are representative of stable operating conditions. 3-7PDF Image | Environmental Technology Verification Report

PDF Search Title:

Environmental Technology Verification ReportOriginal File Name Searched:

Capstone-ETV-Report.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |