PDF Publication Title:

Text from PDF Page: 064

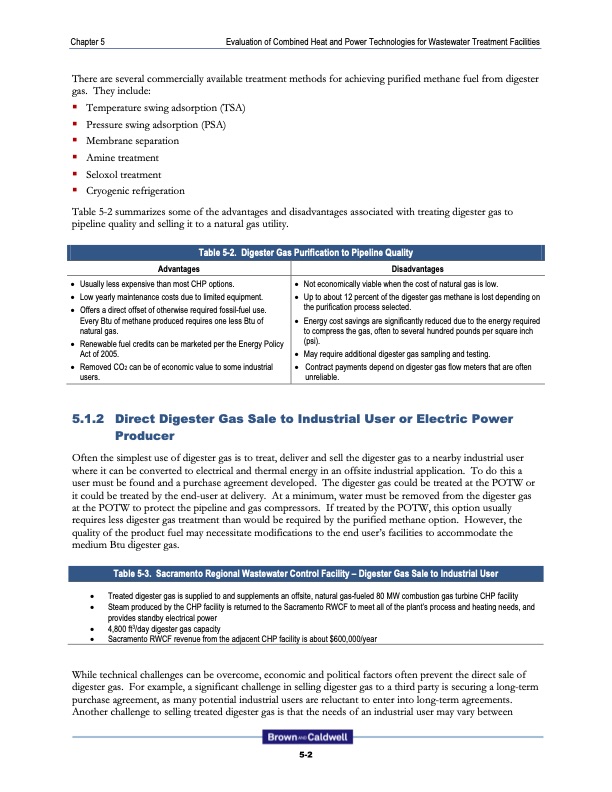

Chapter 5 Evaluation of Combined Heat and Power Technologies for Wastewater Treatment Facilities There are several commercially available treatment methods for achieving purified methane fuel from digester gas. They include: Temperature swing adsorption (TSA) Pressure swing adsorption (PSA) Membrane separation Amine treatment Seloxol treatment Cryogenic refrigeration Table 5-2 summarizes some of the advantages and disadvantages associated with treating digester gas to pipeline quality and selling it to a natural gas utility. Table 5-2. Digester Gas Purification to Pipeline Quality Advantages • Usually less expensive than most CHP options. • Low yearly maintenance costs due to limited equipment. • Offersadirectoffsetofotherwiserequiredfossil-fueluse. Every Btu of methane produced requires one less Btu of natural gas. • RenewablefuelcreditscanbemarketedpertheEnergyPolicy Act of 2005. • Removed CO2 can be of economic value to some industrial users. • • • • • Disadvantages Not economically viable when the cost of natural gas is low. Up to about 12 percent of the digester gas methane is lost depending on the purification process selected. Energy cost savings are significantly reduced due to the energy required to compress the gas, often to several hundred pounds per square inch (psi). May require additional digester gas sampling and testing. Contract payments depend on digester gas flow meters that are often unreliable. 5.1.2 Direct Digester Gas Sale to Industrial User or Electric Power Producer Often the simplest use of digester gas is to treat, deliver and sell the digester gas to a nearby industrial user where it can be converted to electrical and thermal energy in an offsite industrial application. To do this a user must be found and a purchase agreement developed. The digester gas could be treated at the POTW or it could be treated by the end-user at delivery. At a minimum, water must be removed from the digester gas at the POTW to protect the pipeline and gas compressors. If treated by the POTW, this option usually requires less digester gas treatment than would be required by the purified methane option. However, the quality of the product fuel may necessitate modifications to the end user’s facilities to accommodate the medium Btu digester gas. Table 5-3. Sacramento Regional Wastewater Control Facility – Digester Gas Sale to Industrial User • Treated digester gas is supplied to and supplements an offsite, natural gas-fueled 80 MW combustion gas turbine CHP facility • Steam produced by the CHP facility is returned to the Sacramento RWCF to meet all of the plant’s process and heating needs, and provides standby electrical power • 4,800 ft3/day digester gas capacity • Sacramento RWCF revenue from the adjacent CHP facility is about $600,000/year While technical challenges can be overcome, economic and political factors often prevent the direct sale of digester gas. For example, a significant challenge in selling digester gas to a third party is securing a long-term purchase agreement, as many potential industrial users are reluctant to enter into long-term agreements. Another challenge to selling treated digester gas is that the needs of an industrial user may vary between 5-2PDF Image | Combined Heat and Power Technologies for Wastewater Facilities

PDF Search Title:

Combined Heat and Power Technologies for Wastewater FacilitiesOriginal File Name Searched:

300_CHP-EPA-w-Apps.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |