PDF Publication Title:

Text from PDF Page: 052

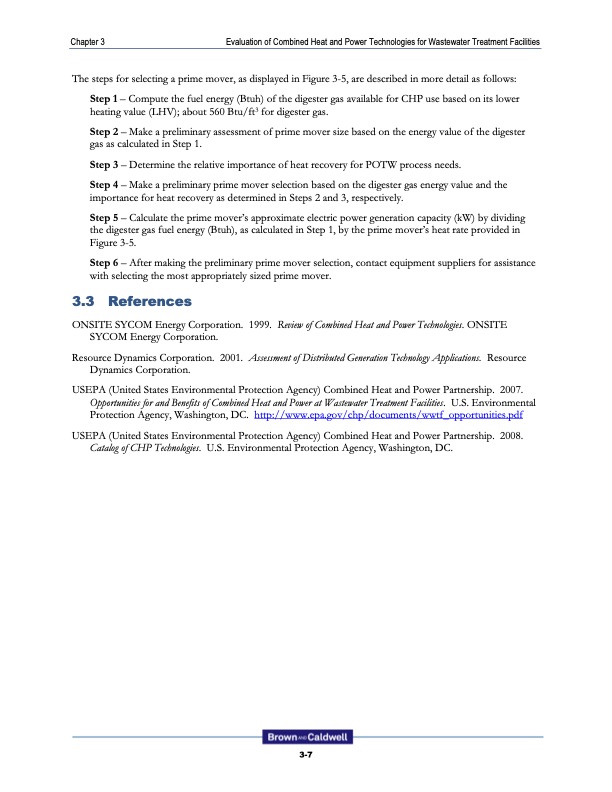

Chapter 3 Evaluation of Combined Heat and Power Technologies for Wastewater Treatment Facilities The steps for selecting a prime mover, as displayed in Figure 3-5, are described in more detail as follows: Step 1 – Compute the fuel energy (Btuh) of the digester gas available for CHP use based on its lower heating value (LHV); about 560 Btu/ft3 for digester gas. Step 2 – Make a preliminary assessment of prime mover size based on the energy value of the digester gas as calculated in Step 1. Step 3 – Determine the relative importance of heat recovery for POTW process needs. Step 4 – Make a preliminary prime mover selection based on the digester gas energy value and the importance for heat recovery as determined in Steps 2 and 3, respectively. Step 5 – Calculate the prime mover’s approximate electric power generation capacity (kW) by dividing the digester gas fuel energy (Btuh), as calculated in Step 1, by the prime mover’s heat rate provided in Figure 3-5. Step 6 – After making the preliminary prime mover selection, contact equipment suppliers for assistance with selecting the most appropriately sized prime mover. 3.3 References ONSITE SYCOM Energy Corporation. 1999. Review of Combined Heat and Power Technologies. ONSITE SYCOM Energy Corporation. Resource Dynamics Corporation. 2001. Assessment of Distributed Generation Technology Applications. Resource Dynamics Corporation. USEPA (United States Environmental Protection Agency) Combined Heat and Power Partnership. 2007. Opportunities for and Benefits ofCombined Heat and Power at Wastewater Treatment Facilities. U.S. Environmental Protection Agency, Washington, DC. http://www.epa.gov/chp/documents/wwtf_opportunities.pdf USEPA (United States Environmental Protection Agency) Combined Heat and Power Partnership. 2008. Catalog ofCHP Technologies. U.S. Environmental Protection Agency, Washington, DC. 3-7PDF Image | Combined Heat and Power Technologies for Wastewater Facilities

PDF Search Title:

Combined Heat and Power Technologies for Wastewater FacilitiesOriginal File Name Searched:

300_CHP-EPA-w-Apps.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |