PDF Publication Title:

Text from PDF Page: 048

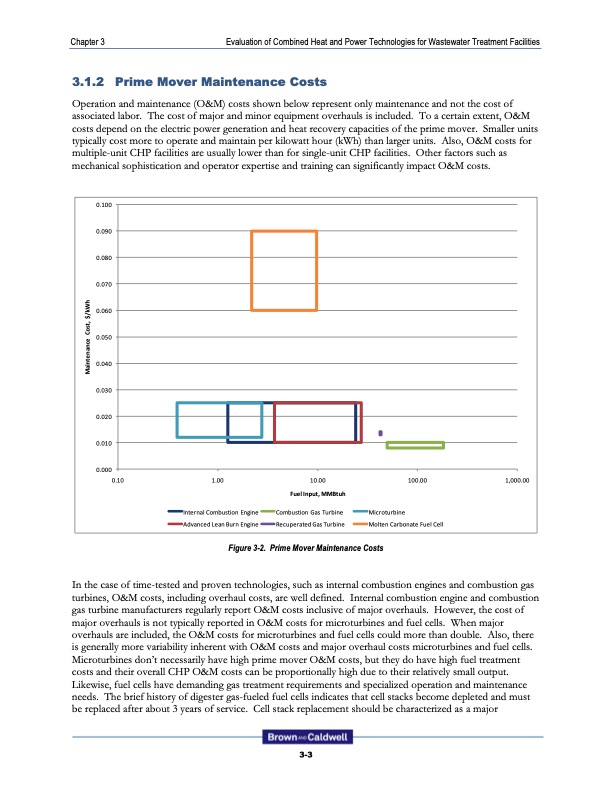

Chapter 3 Evaluation of Combined Heat and Power Technologies for Wastewater Treatment Facilities 3.1.2 Prime Mover Maintenance Costs Operation and maintenance (O&M) costs shown below represent only maintenance and not the cost of associated labor. The cost of major and minor equipment overhauls is included. To a certain extent, O&M costs depend on the electric power generation and heat recovery capacities of the prime mover. Smaller units typically cost more to operate and maintain per kilowatt hour (kWh) than larger units. Also, O&M costs for multiple-unit CHP facilities are usually lower than for single-unit CHP facilities. Other factors such as mechanical sophistication and operator expertise and training can significantly impact O&M costs. 0.100 0.090 0.080 0.070 0.060 0.050 0.040 0.030 0.020 0.010 0.000 0.10 1.00 Internal Combustion Engine Advanced Lean Burn Engine 10.00 100.00 Fuel Input, MMBtuh Combustion Gas Turbine Microturbine Recuperated Gas Turbine Molten Carbonate Fuel Cell 1,000.00 Figure 3-2. Prime Mover Maintenance Costs In the case of time-tested and proven technologies, such as internal combustion engines and combustion gas turbines, O&M costs, including overhaul costs, are well defined. Internal combustion engine and combustion gas turbine manufacturers regularly report O&M costs inclusive of major overhauls. However, the cost of major overhauls is not typically reported in O&M costs for microturbines and fuel cells. When major overhauls are included, the O&M costs for microturbines and fuel cells could more than double. Also, there is generally more variability inherent with O&M costs and major overhaul costs microturbines and fuel cells. Microturbines don’t necessarily have high prime mover O&M costs, but they do have high fuel treatment costs and their overall CHP O&M costs can be proportionally high due to their relatively small output. Likewise, fuel cells have demanding gas treatment requirements and specialized operation and maintenance needs. The brief history of digester gas-fueled fuel cells indicates that cell stacks become depleted and must be replaced after about 3 years of service. Cell stack replacement should be characterized as a major 3-3 Maintenance Cost, $/kWhPDF Image | Combined Heat and Power Technologies for Wastewater Facilities

PDF Search Title:

Combined Heat and Power Technologies for Wastewater FacilitiesOriginal File Name Searched:

300_CHP-EPA-w-Apps.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |