PDF Publication Title:

Text from PDF Page: 026

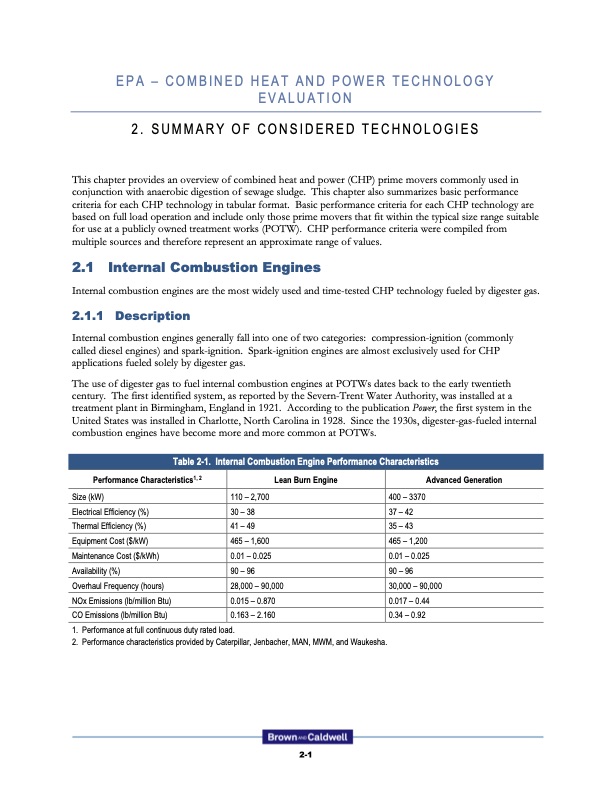

EPA – COMBINED HEAT AND POWER TECHNOLOGY EVALUATION 2. SUMMARY OF CONSIDERED TECHNOLOGIES This chapter provides an overview of combined heat and power (CHP) prime movers commonly used in conjunction with anaerobic digestion of sewage sludge. This chapter also summarizes basic performance criteria for each CHP technology in tabular format. Basic performance criteria for each CHP technology are based on full load operation and include only those prime movers that fit within the typical size range suitable for use at a publicly owned treatment works (POTW). CHP performance criteria were compiled from multiple sources and therefore represent an approximate range of values. 2.1 Internal Combustion Engines Internal combustion engines are the most widely used and time-tested CHP technology fueled by digester gas. 2.1.1 Description Internal combustion engines generally fall into one of two categories: compression-ignition (commonly called diesel engines) and spark-ignition. Spark-ignition engines are almost exclusively used for CHP applications fueled solely by digester gas. The use of digester gas to fuel internal combustion engines at POTWs dates back to the early twentieth century. The first identified system, as reported by the Severn-Trent Water Authority, was installed at a treatment plant in Birmingham, England in 1921. According to the publication Power, the first system in the United States was installed in Charlotte, North Carolina in 1928. Since the 1930s, digester-gas-fueled internal combustion engines have become more and more common at POTWs. Table 2-1. Internal Combustion Engine Performance Characteristics Performance Characteristics1, 2 Size (kW) Electrical Efficiency (%) Thermal Efficiency (%) Equipment Cost ($/kW) Maintenance Cost ($/kWh) Availability (%) Overhaul Frequency (hours) NOx Emissions (lb/million Btu) CO Emissions (lb/million Btu) Lean Burn Engine 110 – 2,700 30–38 41–49 465 – 1,600 0.01 – 0.025 90 – 96 28,000 – 90,000 0.015 – 0.870 0.163 – 2.160 Advanced Generation 400 – 3370 37–42 35–43 465 – 1,200 0.01 – 0.025 90–96 30,000 – 90,000 0.017 – 0.44 0.34 – 0.92 1. Performance at full continuous duty rated load. 2. Performance characteristics provided by Caterpillar, Jenbacher, MAN, MWM, and Waukesha. 2-1PDF Image | Combined Heat and Power Technologies for Wastewater Facilities

PDF Search Title:

Combined Heat and Power Technologies for Wastewater FacilitiesOriginal File Name Searched:

300_CHP-EPA-w-Apps.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |