PDF Publication Title:

Text from PDF Page: 012

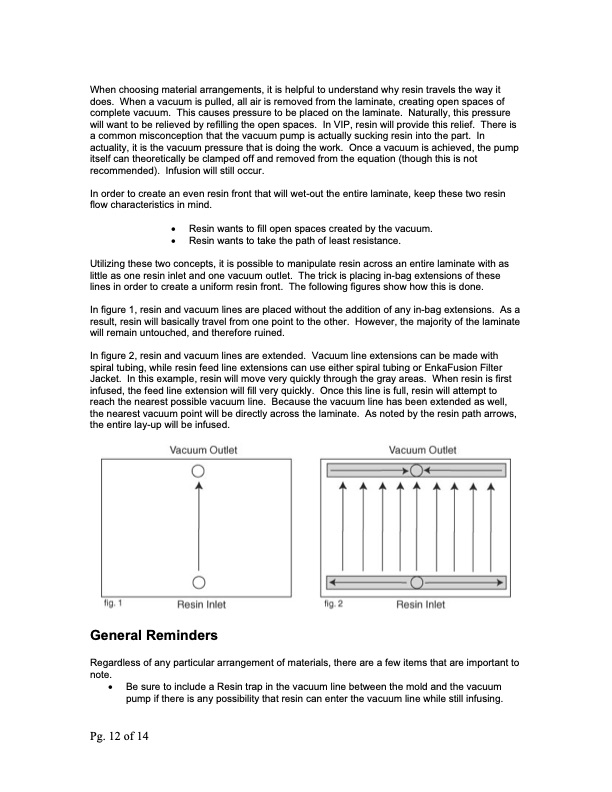

When choosing material arrangements, it is helpful to understand why resin travels the way it does. When a vacuum is pulled, all air is removed from the laminate, creating open spaces of complete vacuum. This causes pressure to be placed on the laminate. Naturally, this pressure will want to be relieved by refilling the open spaces. In VIP, resin will provide this relief. There is a common misconception that the vacuum pump is actually sucking resin into the part. In actuality, it is the vacuum pressure that is doing the work. Once a vacuum is achieved, the pump itself can theoretically be clamped off and removed from the equation (though this is not recommended). Infusion will still occur. In order to create an even resin front that will wet-out the entire laminate, keep these two resin flow characteristics in mind. • Resin wants to fill open spaces created by the vacuum. • Resin wants to take the path of least resistance. Utilizing these two concepts, it is possible to manipulate resin across an entire laminate with as little as one resin inlet and one vacuum outlet. The trick is placing in-bag extensions of these lines in order to create a uniform resin front. The following figures show how this is done. In figure 1, resin and vacuum lines are placed without the addition of any in-bag extensions. As a result, resin will basically travel from one point to the other. However, the majority of the laminate will remain untouched, and therefore ruined. In figure 2, resin and vacuum lines are extended. Vacuum line extensions can be made with spiral tubing, while resin feed line extensions can use either spiral tubing or EnkaFusion Filter Jacket. In this example, resin will move very quickly through the gray areas. When resin is first infused, the feed line extension will fill very quickly. Once this line is full, resin will attempt to reach the nearest possible vacuum line. Because the vacuum line has been extended as well, the nearest vacuum point will be directly across the laminate. As noted by the resin path arrows, the entire lay-up will be infused. General Reminders Regardless of any particular arrangement of materials, there are a few items that are important to note. • Be sure to include a Resin trap in the vacuum line between the mold and the vacuum pump if there is any possibility that resin can enter the vacuum line while still infusing. Pg. 12 of 14PDF Image | Vacuum Infusion

PDF Search Title:

Vacuum InfusionOriginal File Name Searched:

FibreGlast_Vacuum_infusion_process.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |