PDF Publication Title:

Text from PDF Page: 047

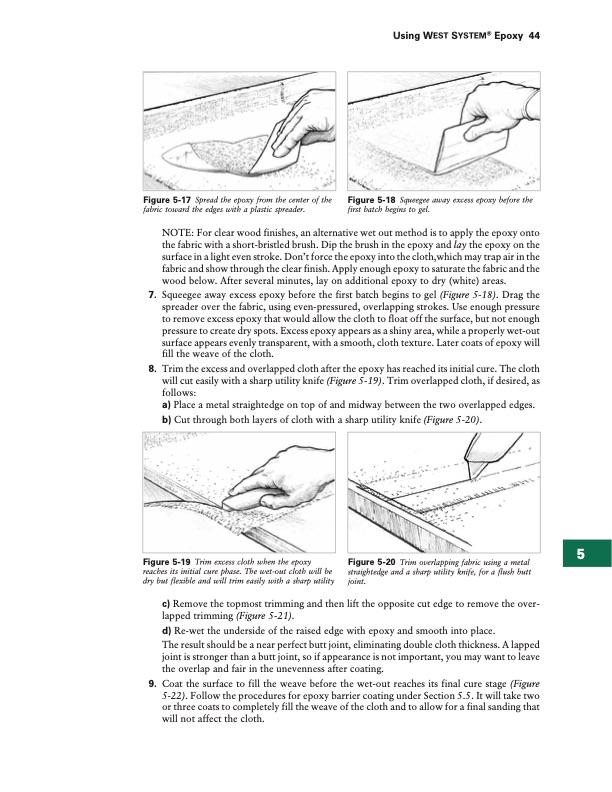

Figure 5-17 Spread the epoxy from the center of the Figure 5-18 Squeegee away excess epoxy before the fabric toward the edges with a plastic spreader. first batch begins to gel. NOTE: For clear wood finishes, an alternative wet out method is to apply the epoxy onto the fabric with a short-bristled brush. Dip the brush in the epoxy and lay the epoxy on the surface in a light even stroke. Don’t force the epoxy into the cloth,which may trap air in the fabric and show through the clear finish. Apply enough epoxy to saturate the fabric and the wood below. After several minutes, lay on additional epoxy to dry (white) areas. 7. Squeegee away excess epoxy before the first batch begins to gel (Figure 5-18). Drag the spreader over the fabric, using even-pressured, overlapping strokes. Use enough pressure to remove excess epoxy that would allow the cloth to float off the surface, but not enough pressure to create dry spots. Excess epoxy appears as a shiny area, while a properly wet-out surface appears evenly transparent, with a smooth, cloth texture. Later coats of epoxy will fill the weave of the cloth. 8. Trimtheexcessandoverlappedclothaftertheepoxyhasreacheditsinitialcure.Thecloth will cut easily with a sharp utility knife (Figure 5-19). Trim overlapped cloth, if desired, as follows: a) Place a metal straightedge on top of and midway between the two overlapped edges. b) Cut through both layers of cloth with a sharp utility knife (Figure 5-20). Using WEST SYSTEM® Epoxy 44 Figure 5-19 Trim excess cloth when the epoxy reaches its initial cure phase. The wet-out cloth will be dry but flexible and will trim easily with a sharp utility Figure 5-20 Trim overlapping fabric using a metal straightedge and a sharp utility knife, for a flush butt joint. c) Remove the topmost trimming and then lift the opposite cut edge to remove the over- lapped trimming (Figure 5-21). d) Re-wet the underside of the raised edge with epoxy and smooth into place. The result should be a near perfect butt joint, eliminating double cloth thickness. A lapped joint is stronger than a butt joint, so if appearance is not important, you may want to leave the overlap and fair in the unevenness after coating. 9. Coat the surface to fill the weave before the wet-out reaches its final cure stage (Figure 5-22). Follow the procedures for epoxy barrier coating under Section 5.5. It will take two or three coats to completely fill the weave of the cloth and to allow for a final sanding that will not affect the cloth. 5PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |