PDF Publication Title:

Text from PDF Page: 043

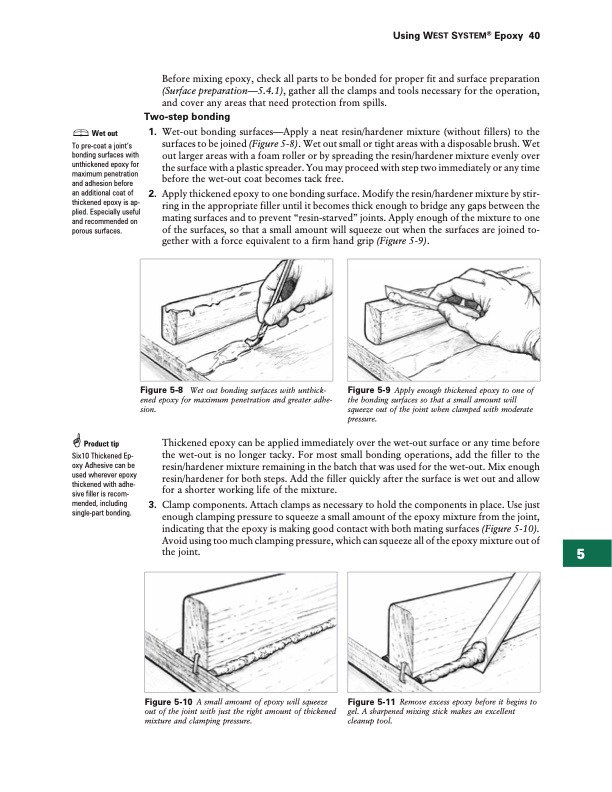

§ Wet out To pre-coat a joint’s bonding surfaces with unthickened epoxy for maximum penetration and adhesion before an additional coat of thickened epoxy is ap- plied. Especially useful and recommended on porous surfaces. Before mixing epoxy, check all parts to be bonded for proper fit and surface preparation (Surface preparation—5.4.1), gather all the clamps and tools necessary for the operation, and cover any areas that need protection from spills. Two-step bonding 1. Wet-out bonding surfaces—Apply a neat resin/hardener mixture (without fillers) to the surfaces to be joined (Figure 5-8). Wet out small or tight areas with a disposable brush. Wet out larger areas with a foam roller or by spreading the resin/hardener mixture evenly over the surface with a plastic spreader. You may proceed with step two immediately or any time before the wet-out coat becomes tack free. 2. Applythickenedepoxytoonebondingsurface.Modifytheresin/hardenermixturebystir- ring in the appropriate filler until it becomes thick enough to bridge any gaps between the mating surfaces and to prevent “resin-starved” joints. Apply enough of the mixture to one of the surfaces, so that a small amount will squeeze out when the surfaces are joined to- gether with a force equivalent to a firm hand grip (Figure 5-9). GProduct tip Six10 Thickened Ep- oxy Adhesive can be used wherever epoxy thickened with adhe- sive filler is recom- mended, including single-part bonding. Thickened epoxy can be applied immediately over the wet-out surface or any time before the wet-out is no longer tacky. For most small bonding operations, add the filler to the resin/hardener mixture remaining in the batch that was used for the wet-out. Mix enough resin/hardener for both steps. Add the filler quickly after the surface is wet out and allow for a shorter working life of the mixture. 3. Clamp components. Attach clamps as necessary to hold the components in place. Use just enough clamping pressure to squeeze a small amount of the epoxy mixture from the joint, indicating that the epoxy is making good contact with both mating surfaces (Figure 5-10). Avoid using too much clamping pressure, which can squeeze all of the epoxy mixture out of the joint. Figure 5-8 Wet out bonding surfaces with unthick- ened epoxy for maximum penetration and greater adhe- sion. Figure 5-9 Apply enough thickened epoxy to one of the bonding surfaces so that a small amount will squeeze out of the joint when clamped with moderate pressure. Using WEST SYSTEM® Epoxy 40 Figure 5-10 A small amount of epoxy will squeeze out of the joint with just the right amount of thickened mixture and clamping pressure. Figure 5-11 Remove excess epoxy before it begins to gel. A sharpened mixing stick makes an excellent cleanup tool. 5PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |