PDF Publication Title:

Text from PDF Page: 029

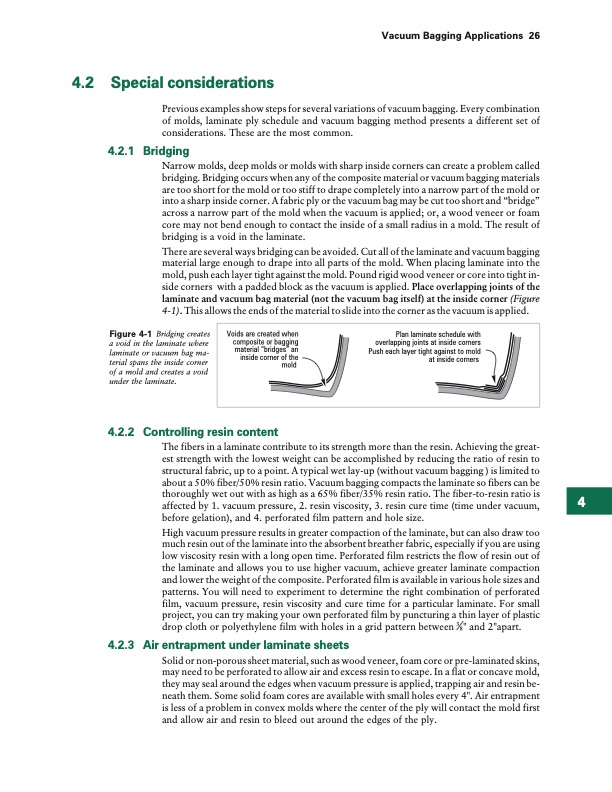

4.2 Special considerations Previous examples show steps for several variations of vacuum bagging. Every combination of molds, laminate ply schedule and vacuum bagging method presents a different set of considerations. These are the most common. 4.2.1 Bridging Narrow molds, deep molds or molds with sharp inside corners can create a problem called bridging. Bridging occurs when any of the composite material or vacuum bagging materials are too short for the mold or too stiff to drape completely into a narrow part of the mold or into a sharp inside corner. A fabric ply or the vacuum bag may be cut too short and “bridge” across a narrow part of the mold when the vacuum is applied; or, a wood veneer or foam core may not bend enough to contact the inside of a small radius in a mold. The result of bridging is a void in the laminate. There are several ways bridging can be avoided. Cut all of the laminate and vacuum bagging material large enough to drape into all parts of the mold. When placing laminate into the mold, push each layer tight against the mold. Pound rigid wood veneer or core into tight in- side corners with a padded block as the vacuum is applied. Place overlapping joints of the laminate and vacuum bag material (not the vacuum bag itself) at the inside corner (Figure 4-1). This allows the ends of the material to slide into the corner as the vacuum is applied. Figure 4-1 Bridging creates a void in the laminate where laminate or vacuum bag ma- terial spans the inside corner of a mold and creates a void under the laminate. 4.2.2 Controlling resin content The fibers in a laminate contribute to its strength more than the resin. Achieving the great- est strength with the lowest weight can be accomplished by reducing the ratio of resin to structural fabric, up to a point. A typical wet lay-up (without vacuum bagging ) is limited to about a 50% fiber/50% resin ratio. Vacuum bagging compacts the laminate so fibers can be thoroughly wet out with as high as a 65% fiber/35% resin ratio. The fiber-to-resin ratio is affected by 1. vacuum pressure, 2. resin viscosity, 3. resin cure time (time under vacuum, before gelation), and 4. perforated film pattern and hole size. High vacuum pressure results in greater compaction of the laminate, but can also draw too much resin out of the laminate into the absorbent breather fabric, especially if you are using low viscosity resin with a long open time. Perforated film restricts the flow of resin out of the laminate and allows you to use higher vacuum, achieve greater laminate compaction and lower the weight of the composite. Perforated film is available in various hole sizes and patterns. You will need to experiment to determine the right combination of perforated film, vacuum pressure, resin viscosity and cure time for a particular laminate. For small project, you can try making your own perforated film by puncturing a thin layer of plastic drop cloth or polyethylene film with holes in a grid pattern between 38" and 2"apart. 4.2.3 Air entrapment under laminate sheets Solid or non-porous sheet material, such as wood veneer, foam core or pre-laminated skins, may need to be perforated to allow air and excess resin to escape. In a flat or concave mold, they may seal around the edges when vacuum pressure is applied, trapping air and resin be- neath them. Some solid foam cores are available with small holes every 4". Air entrapment is less of a problem in convex molds where the center of the ply will contact the mold first and allow air and resin to bleed out around the edges of the ply. Vacuum Bagging Applications 26 Voids are created when composite or bagging material “bridges” an inside corner of the mold Plan laminate schedule with overlapping joints at inside corners Push each layer tight against to mold at inside corners 4PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |