PDF Publication Title:

Text from PDF Page: 015

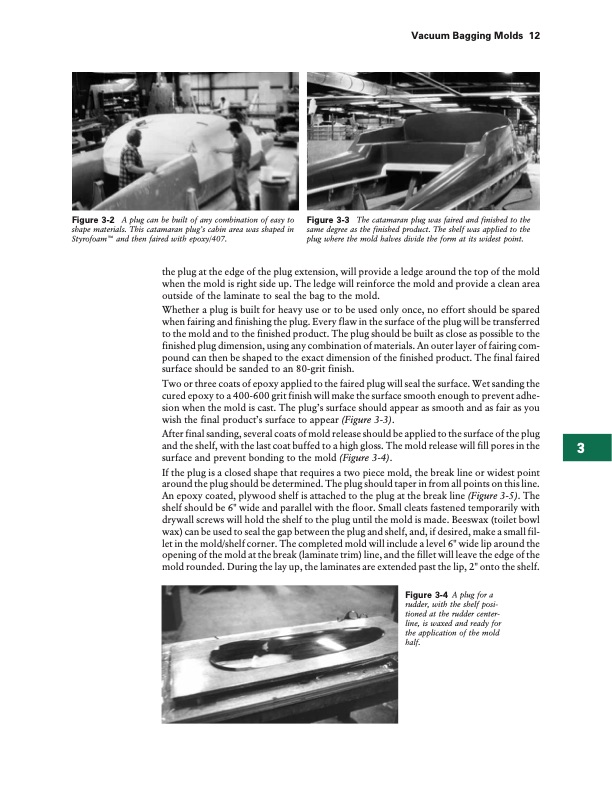

Figure 3-2 A plug can be built of any combination of easy to shape materials. This catamaran plug’s cabin area was shaped in StyrofoamTM and then faired with epoxy/407. Figure 3-3 The catamaran plug was faired and finished to the same degree as the finished product. The shelf was applied to the plug where the mold halves divide the form at its widest point. the plug at the edge of the plug extension, will provide a ledge around the top of the mold when the mold is right side up. The ledge will reinforce the mold and provide a clean area outside of the laminate to seal the bag to the mold. Whether a plug is built for heavy use or to be used only once, no effort should be spared when fairing and finishing the plug. Every flaw in the surface of the plug will be transferred to the mold and to the finished product. The plug should be built as close as possible to the finished plug dimension, using any combination of materials. An outer layer of fairing com- pound can then be shaped to the exact dimension of the finished product. The final faired surface should be sanded to an 80-grit finish. Two or three coats of epoxy applied to the faired plug will seal the surface. Wet sanding the cured epoxy to a 400-600 grit finish will make the surface smooth enough to prevent adhe- sion when the mold is cast. The plug’s surface should appear as smooth and as fair as you wish the final product’s surface to appear (Figure 3-3). After final sanding, several coats of mold release should be applied to the surface of the plug and the shelf, with the last coat buffed to a high gloss. The mold release will fill pores in the surface and prevent bonding to the mold (Figure 3-4). If the plug is a closed shape that requires a two piece mold, the break line or widest point around the plug should be determined. The plug should taper in from all points on this line. An epoxy coated, plywood shelf is attached to the plug at the break line (Figure 3-5). The shelf should be 6" wide and parallel with the floor. Small cleats fastened temporarily with drywall screws will hold the shelf to the plug until the mold is made. Beeswax (toilet bowl wax) can be used to seal the gap between the plug and shelf, and, if desired, make a small fil- let in the mold/shelf corner. The completed mold will include a level 6" wide lip around the opening of the mold at the break (laminate trim) line, and the fillet will leave the edge of the mold rounded. During the lay up, the laminates are extended past the lip, 2" onto the shelf. Figure 3-4 A plug for a rudder, with the shelf posi- tioned at the rudder center- line, is waxed and ready for the application of the mold half. Vacuum Bagging Molds 12 3PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |