PDF Publication Title:

Text from PDF Page: 012

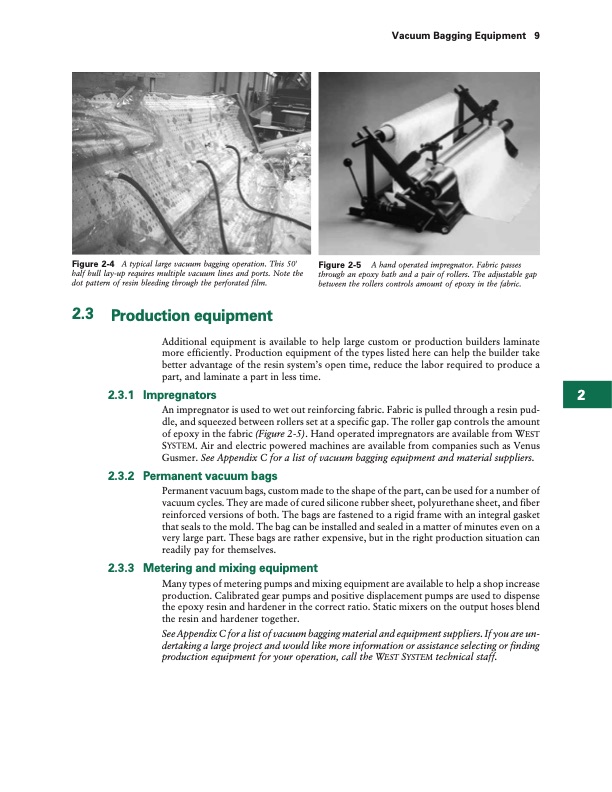

Figure 2-4 A typical large vacuum bagging operation. This 50' half hull lay-up requires multiple vacuum lines and ports. Note the dot pattern of resin bleeding through the perforated film. Figure 2-5 A hand operated impregnator. Fabric passes through an epoxy bath and a pair of rollers. The adjustable gap between the rollers controls amount of epoxy in the fabric. 2.3 Production equipment Additional equipment is available to help large custom or production builders laminate more efficiently. Production equipment of the types listed here can help the builder take better advantage of the resin system’s open time, reduce the labor required to produce a part, and laminate a part in less time. 2.3.1 Impregnators An impregnator is used to wet out reinforcing fabric. Fabric is pulled through a resin pud- dle, and squeezed between rollers set at a specific gap. The roller gap controls the amount of epoxy in the fabric (Figure 2-5). Hand operated impregnators are available from WEST SYSTEM. Air and electric powered machines are available from companies such as Venus Gusmer. See Appendix C for a list of vacuum bagging equipment and material suppliers. 2.3.2 Permanent vacuum bags Permanent vacuum bags, custom made to the shape of the part, can be used for a number of vacuum cycles. They are made of cured silicone rubber sheet, polyurethane sheet, and fiber reinforced versions of both. The bags are fastened to a rigid frame with an integral gasket that seals to the mold. The bag can be installed and sealed in a matter of minutes even on a very large part. These bags are rather expensive, but in the right production situation can readily pay for themselves. 2.3.3 Metering and mixing equipment Many types of metering pumps and mixing equipment are available to help a shop increase production. Calibrated gear pumps and positive displacement pumps are used to dispense the epoxy resin and hardener in the correct ratio. Static mixers on the output hoses blend the resin and hardener together. See Appendix C for a list of vacuum bagging material and equipment suppliers. If you are un- dertaking a large project and would like more information or assistance selecting or finding production equipment for your operation, call the WEST SYSTEM technical staff. Vacuum Bagging Equipment 9 2PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |