PDF Publication Title:

Text from PDF Page: 004

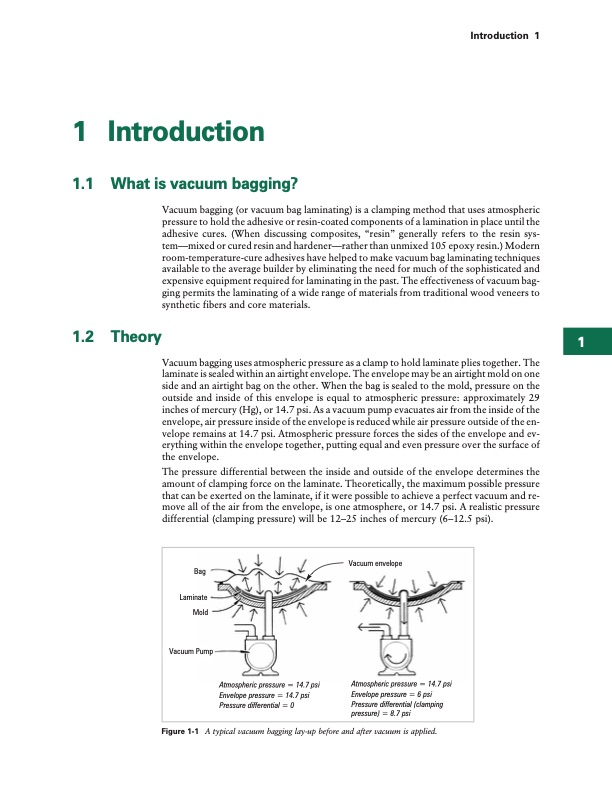

1 Introduction 1.1 What is vacuum bagging? Vacuum bagging (or vacuum bag laminating) is a clamping method that uses atmospheric pressure to hold the adhesive or resin-coated components of a lamination in place until the adhesive cures. (When discussing composites, “resin” generally refers to the resin sys- tem—mixed or cured resin and hardener—rather than unmixed 105 epoxy resin.) Modern room-temperature-cure adhesives have helped to make vacuum bag laminating techniques available to the average builder by eliminating the need for much of the sophisticated and expensive equipment required for laminating in the past. The effectiveness of vacuum bag- ging permits the laminating of a wide range of materials from traditional wood veneers to synthetic fibers and core materials. 1.2 Theory Vacuum bagging uses atmospheric pressure as a clamp to hold laminate plies together. The laminate is sealed within an airtight envelope. The envelope may be an airtight mold on one side and an airtight bag on the other. When the bag is sealed to the mold, pressure on the outside and inside of this envelope is equal to atmospheric pressure: approximately 29 inches of mercury (Hg), or 14.7 psi. As a vacuum pump evacuates air from the inside of the envelope, air pressure inside of the envelope is reduced while air pressure outside of the en- velope remains at 14.7 psi. Atmospheric pressure forces the sides of the envelope and ev- erything within the envelope together, putting equal and even pressure over the surface of the envelope. The pressure differential between the inside and outside of the envelope determines the amount of clamping force on the laminate. Theoretically, the maximum possible pressure that can be exerted on the laminate, if it were possible to achieve a perfect vacuum and re- move all of the air from the envelope, is one atmosphere, or 14.7 psi. A realistic pressure differential (clamping pressure) will be 12–25 inches of mercury (6–12.5 psi). Introduction 1 Vacuum Pump Bag Laminate Mold Vacuum envelope Atmospheric pressure = 14.7 psi Envelope pressure = 6 psi Pressure differential (clamping pressure) = 8.7 psi Atmospheric pressure = 14.7 psi Envelope pressure = 14.7 psi Pressure differential = 0 Figure 1-1 A typical vacuum bagging lay-up before and after vacuum is applied. 1PDF Image | Vacuum Bagging Techniques 002150

PDF Search Title:

Vacuum Bagging Techniques 002150Original File Name Searched:

VacuumBag-7th-Ed.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |