PDF Publication Title:

Text from PDF Page: 011

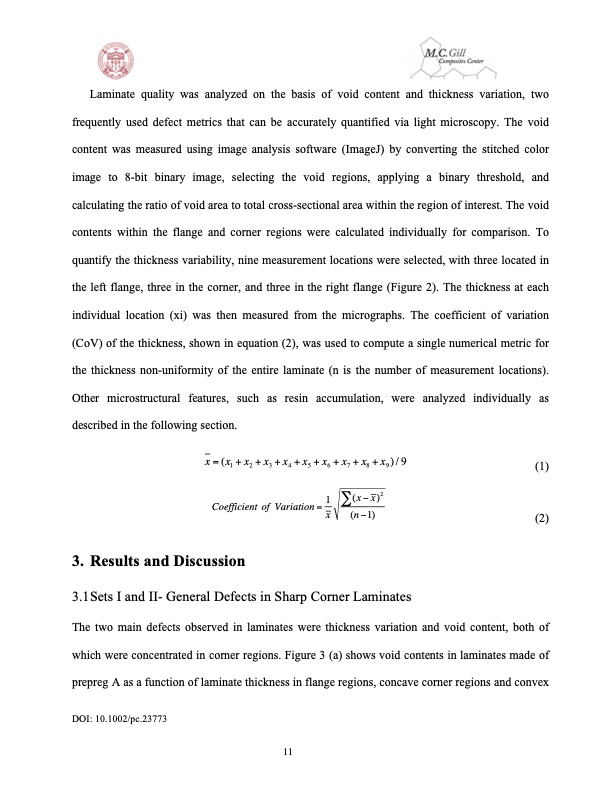

Laminate quality was analyzed on the basis of void content and thickness variation, two frequently used defect metrics that can be accurately quantified via light microscopy. The void content was measured using image analysis software (ImageJ) by converting the stitched color image to 8-bit binary image, selecting the void regions, applying a binary threshold, and calculating the ratio of void area to total cross-sectional area within the region of interest. The void contents within the flange and corner regions were calculated individually for comparison. To quantify the thickness variability, nine measurement locations were selected, with three located in the left flange, three in the corner, and three in the right flange (Figure 2). The thickness at each individual location (xi) was then measured from the micrographs. The coefficient of variation (CoV) of the thickness, shown in equation (2), was used to compute a single numerical metric for the thickness non-uniformity of the entire laminate (n is the number of measurement locations). Other microstructural features, such as resin accumulation, were analyzed individually as described in the following section. x=(x1 +x2 +x3 +x4 +x5 +x6 +x7 +x8 +x9)/9 Coefficient of Variation = 1 ∑(x − x )2 x (n−1) 3. Results and Discussion 3.1Sets I and II- General Defects in Sharp Corner Laminates (1) (2) The two main defects observed in laminates were thickness variation and void content, both of which were concentrated in corner regions. Figure 3 (a) shows void contents in laminates made of prepreg A as a function of laminate thickness in flange regions, concave corner regions and convex DOI: 10.1002/pc.23773 11PDF Image | Vacuum Bag-Only Prepregs

PDF Search Title:

Vacuum Bag-Only PrepregsOriginal File Name Searched:

J224.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |