PDF Publication Title:

Text from PDF Page: 007

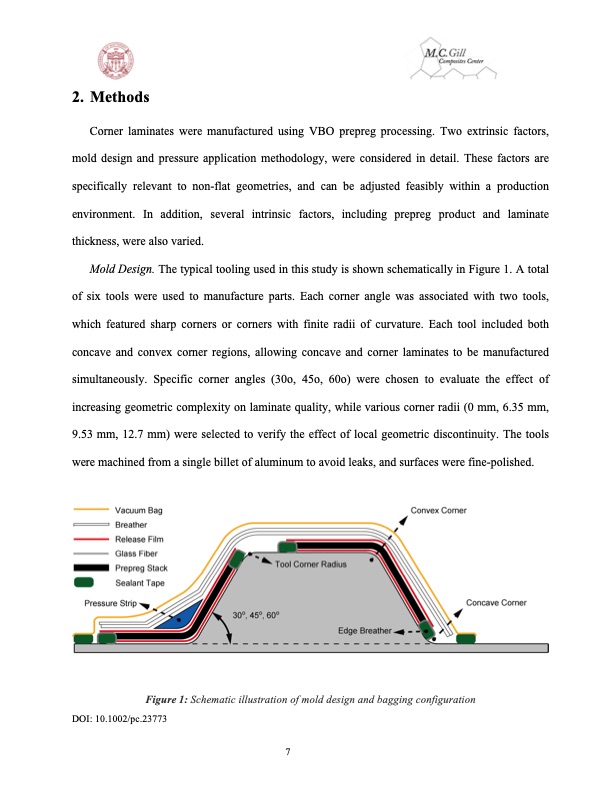

2. Methods Corner laminates were manufactured using VBO prepreg processing. Two extrinsic factors, mold design and pressure application methodology, were considered in detail. These factors are specifically relevant to non-flat geometries, and can be adjusted feasibly within a production environment. In addition, several intrinsic factors, including prepreg product and laminate thickness, were also varied. Mold Design. The typical tooling used in this study is shown schematically in Figure 1. A total of six tools were used to manufacture parts. Each corner angle was associated with two tools, which featured sharp corners or corners with finite radii of curvature. Each tool included both concave and convex corner regions, allowing concave and corner laminates to be manufactured simultaneously. Specific corner angles (30o, 45o, 60o) were chosen to evaluate the effect of increasing geometric complexity on laminate quality, while various corner radii (0 mm, 6.35 mm, 9.53 mm, 12.7 mm) were selected to verify the effect of local geometric discontinuity. The tools were machined from a single billet of aluminum to avoid leaks, and surfaces were fine-polished. Figure 1: Schematic illustration of mold design and bagging configuration DOI: 10.1002/pc.23773 7PDF Image | Vacuum Bag-Only Prepregs

PDF Search Title:

Vacuum Bag-Only PrepregsOriginal File Name Searched:

J224.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |