PDF Publication Title:

Text from PDF Page: 010

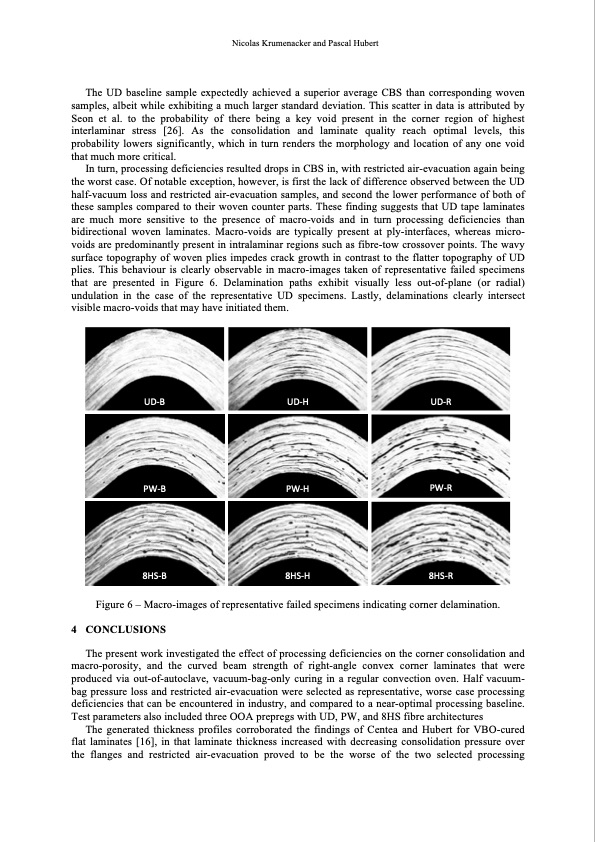

Nicolas Krumenacker and Pascal Hubert The UD baseline sample expectedly achieved a superior average CBS than corresponding woven samples, albeit while exhibiting a much larger standard deviation. This scatter in data is attributed by Seon et al. to the probability of there being a key void present in the corner region of highest interlaminar stress [26]. As the consolidation and laminate quality reach optimal levels, this probability lowers significantly, which in turn renders the morphology and location of any one void that much more critical. In turn, processing deficiencies resulted drops in CBS in, with restricted air-evacuation again being the worst case. Of notable exception, however, is first the lack of difference observed between the UD half-vacuum loss and restricted air-evacuation samples, and second the lower performance of both of these samples compared to their woven counter parts. These finding suggests that UD tape laminates are much more sensitive to the presence of macro-voids and in turn processing deficiencies than bidirectional woven laminates. Macro-voids are typically present at ply-interfaces, whereas micro- voids are predominantly present in intralaminar regions such as fibre-tow crossover points. The wavy surface topography of woven plies impedes crack growth in contrast to the flatter topography of UD plies. This behaviour is clearly observable in macro-images taken of representative failed specimens that are presented in Figure 6. Delamination paths exhibit visually less out-of-plane (or radial) undulation in the case of the representative UD specimens. Lastly, delaminations clearly intersect visible macro-voids that may have initiated them. Figure 6 – Macro-images of representative failed specimens indicating corner delamination. 4 CONCLUSIONS The present work investigated the effect of processing deficiencies on the corner consolidation and macro-porosity, and the curved beam strength of right-angle convex corner laminates that were produced via out-of-autoclave, vacuum-bag-only curing in a regular convection oven. Half vacuum- bag pressure loss and restricted air-evacuation were selected as representative, worse case processing deficiencies that can be encountered in industry, and compared to a near-optimal processing baseline. Test parameters also included three OOA prepregs with UD, PW, and 8HS fibre architectures The generated thickness profiles corroborated the findings of Centea and Hubert for VBO-cured flat laminates [16], in that laminate thickness increased with decreasing consolidation pressure over the flanges and restricted air-evacuation proved to be the worse of the two selected processing UD-B UD-H UD-R PW-B PW-H PW-R 8HS-B 8HS-H 8HS-RPDF Image | VACUUM-BAG-ONLY COMPLEX-SHAPE PREPREG LAMINATE

PDF Search Title:

VACUUM-BAG-ONLY COMPLEX-SHAPE PREPREG LAMINATEOriginal File Name Searched:

paper-2206.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |