PDF Publication Title:

Text from PDF Page: 004

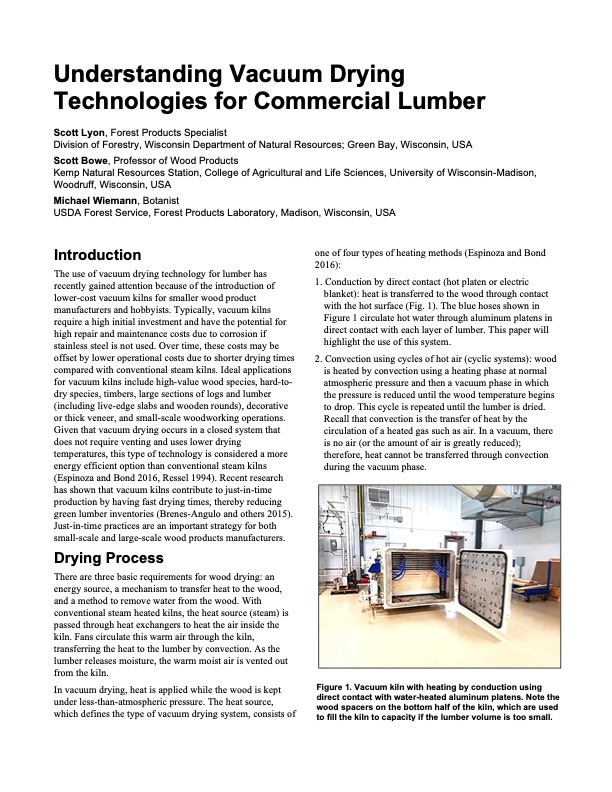

Understanding Vacuum Drying Technologies for Commercial Lumber Scott Lyon, Forest Products Specialist Division of Forestry, Wisconsin Department of Natural Resources; Green Bay, Wisconsin, USA Scott Bowe, Professor of Wood Products Kemp Natural Resources Station, College of Agricultural and Life Sciences, University of Wisconsin-Madison, Woodruff, Wisconsin, USA Michael Wiemann, Botanist USDA Forest Service, Forest Products Laboratory, Madison, Wisconsin, USA Introduction The use of vacuum drying technology for lumber has recently gained attention because of the introduction of lower-cost vacuum kilns for smaller wood product manufacturers and hobbyists. Typically, vacuum kilns require a high initial investment and have the potential for high repair and maintenance costs due to corrosion if stainless steel is not used. Over time, these costs may be offset by lower operational costs due to shorter drying times compared with conventional steam kilns. Ideal applications for vacuum kilns include high-value wood species, hard-to- dry species, timbers, large sections of logs and lumber (including live-edge slabs and wooden rounds), decorative or thick veneer, and small-scale woodworking operations. Given that vacuum drying occurs in a closed system that does not require venting and uses lower drying temperatures, this type of technology is considered a more energy efficient option than conventional steam kilns (Espinoza and Bond 2016, Ressel 1994). Recent research has shown that vacuum kilns contribute to just-in-time production by having fast drying times, thereby reducing green lumber inventories (Brenes-Angulo and others 2015). Just-in-time practices are an important strategy for both small-scale and large-scale wood products manufacturers. Drying Process There are three basic requirements for wood drying: an energy source, a mechanism to transfer heat to the wood, and a method to remove water from the wood. With conventional steam heated kilns, the heat source (steam) is passed through heat exchangers to heat the air inside the kiln. Fans circulate this warm air through the kiln, transferring the heat to the lumber by convection. As the lumber releases moisture, the warm moist air is vented out from the kiln. In vacuum drying, heat is applied while the wood is kept under less-than-atmospheric pressure. The heat source, which defines the type of vacuum drying system, consists of one of four types of heating methods (Espinoza and Bond 2016): 1. Conduction by direct contact (hot platen or electric blanket): heat is transferred to the wood through contact with the hot surface (Fig. 1). The blue hoses shown in Figure 1 circulate hot water through aluminum platens in direct contact with each layer of lumber. This paper will highlight the use of this system. 2. Convection using cycles of hot air (cyclic systems): wood is heated by convection using a heating phase at normal atmospheric pressure and then a vacuum phase in which the pressure is reduced until the wood temperature begins to drop. This cycle is repeated until the lumber is dried. Recall that convection is the transfer of heat by the circulation of a heated gas such as air. In a vacuum, there is no air (or the amount of air is greatly reduced); therefore, heat cannot be transferred through convection during the vacuum phase. Figure 1. Vacuum kiln with heating by conduction using direct contact with water-heated aluminum platens. Note the wood spacers on the bottom half of the kiln, which are used to fill the kiln to capacity if the lumber volume is too small.PDF Image | Understanding Vacuum Drying Technologies for Commercial Lumber

PDF Search Title:

Understanding Vacuum Drying Technologies for Commercial LumberOriginal File Name Searched:

fpl_gtr287-final.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |