PDF Publication Title:

Text from PDF Page: 004

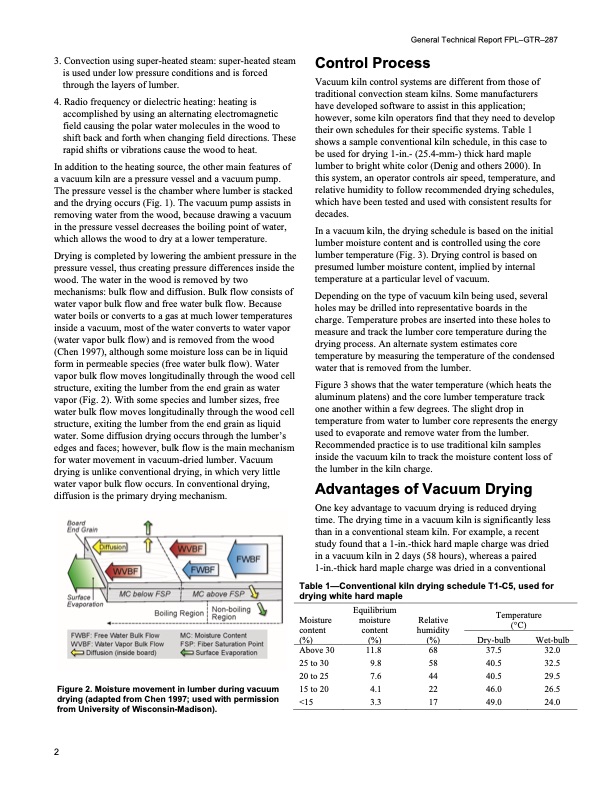

3. Convection using super-heated steam: super-heated steam is used under low pressure conditions and is forced through the layers of lumber. 4. Radio frequency or dielectric heating: heating is accomplished by using an alternating electromagnetic field causing the polar water molecules in the wood to shift back and forth when changing field directions. These rapid shifts or vibrations cause the wood to heat. In addition to the heating source, the other main features of a vacuum kiln are a pressure vessel and a vacuum pump. The pressure vessel is the chamber where lumber is stacked and the drying occurs (Fig. 1). The vacuum pump assists in removing water from the wood, because drawing a vacuum in the pressure vessel decreases the boiling point of water, which allows the wood to dry at a lower temperature. Drying is completed by lowering the ambient pressure in the pressure vessel, thus creating pressure differences inside the wood. The water in the wood is removed by two mechanisms: bulk flow and diffusion. Bulk flow consists of water vapor bulk flow and free water bulk flow. Because water boils or converts to a gas at much lower temperatures inside a vacuum, most of the water converts to water vapor (water vapor bulk flow) and is removed from the wood (Chen 1997), although some moisture loss can be in liquid form in permeable species (free water bulk flow). Water vapor bulk flow moves longitudinally through the wood cell structure, exiting the lumber from the end grain as water vapor (Fig. 2). With some species and lumber sizes, free water bulk flow moves longitudinally through the wood cell structure, exiting the lumber from the end grain as liquid water. Some diffusion drying occurs through the lumber’s edges and faces; however, bulk flow is the main mechanism for water movement in vacuum-dried lumber. Vacuum drying is unlike conventional drying, in which very little water vapor bulk flow occurs. In conventional drying, diffusion is the primary drying mechanism. General Technical Report FPL–GTR–287 Control Process Vacuum kiln control systems are different from those of traditional convection steam kilns. Some manufacturers have developed software to assist in this application; however, some kiln operators find that they need to develop their own schedules for their specific systems. Table 1 shows a sample conventional kiln schedule, in this case to be used for drying 1-in.- (25.4-mm-) thick hard maple lumber to bright white color (Denig and others 2000). In this system, an operator controls air speed, temperature, and relative humidity to follow recommended drying schedules, which have been tested and used with consistent results for decades. In a vacuum kiln, the drying schedule is based on the initial lumber moisture content and is controlled using the core lumber temperature (Fig. 3). Drying control is based on presumed lumber moisture content, implied by internal temperature at a particular level of vacuum. Depending on the type of vacuum kiln being used, several holes may be drilled into representative boards in the charge. Temperature probes are inserted into these holes to measure and track the lumber core temperature during the drying process. An alternate system estimates core temperature by measuring the temperature of the condensed water that is removed from the lumber. Figure 3 shows that the water temperature (which heats the aluminum platens) and the core lumber temperature track one another within a few degrees. The slight drop in temperature from water to lumber core represents the energy used to evaporate and remove water from the lumber. Recommended practice is to use traditional kiln samples inside the vacuum kiln to track the moisture content loss of the lumber in the kiln charge. Advantages of Vacuum Drying One key advantage to vacuum drying is reduced drying time. The drying time in a vacuum kiln is significantly less than in a conventional steam kiln. For example, a recent study found that a 1-in.-thick hard maple charge was dried in a vacuum kiln in 2 days (58 hours), whereas a paired 1-in.-thick hard maple charge was dried in a conventional Figure 2. Moisture movement in lumber during vacuum drying (adapted from Chen 1997; used with permission from University of Wisconsin-Madison). Table 1—Conventional kiln drying schedule T1-C5, used for drying white hard maple Moisture content (%) Above 30 Equilibrium moisture Relative Temperature (°C) content humidity (%) (%) Dry-bulb Wet-bulb 32.0 32.5 29.5 26.5 24.0 11.8 68 37.5 9.8 58 40.5 7.6 44 40.5 4.1 22 46.0 25 to 30 20 to 25 15 to 20 <15 3.3 17 49.0 2PDF Image | Understanding Vacuum Drying Tech for Commercial Lumber

PDF Search Title:

Understanding Vacuum Drying Tech for Commercial LumberOriginal File Name Searched:

fpl_gtr287.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |