PDF Publication Title:

Text from PDF Page: 002

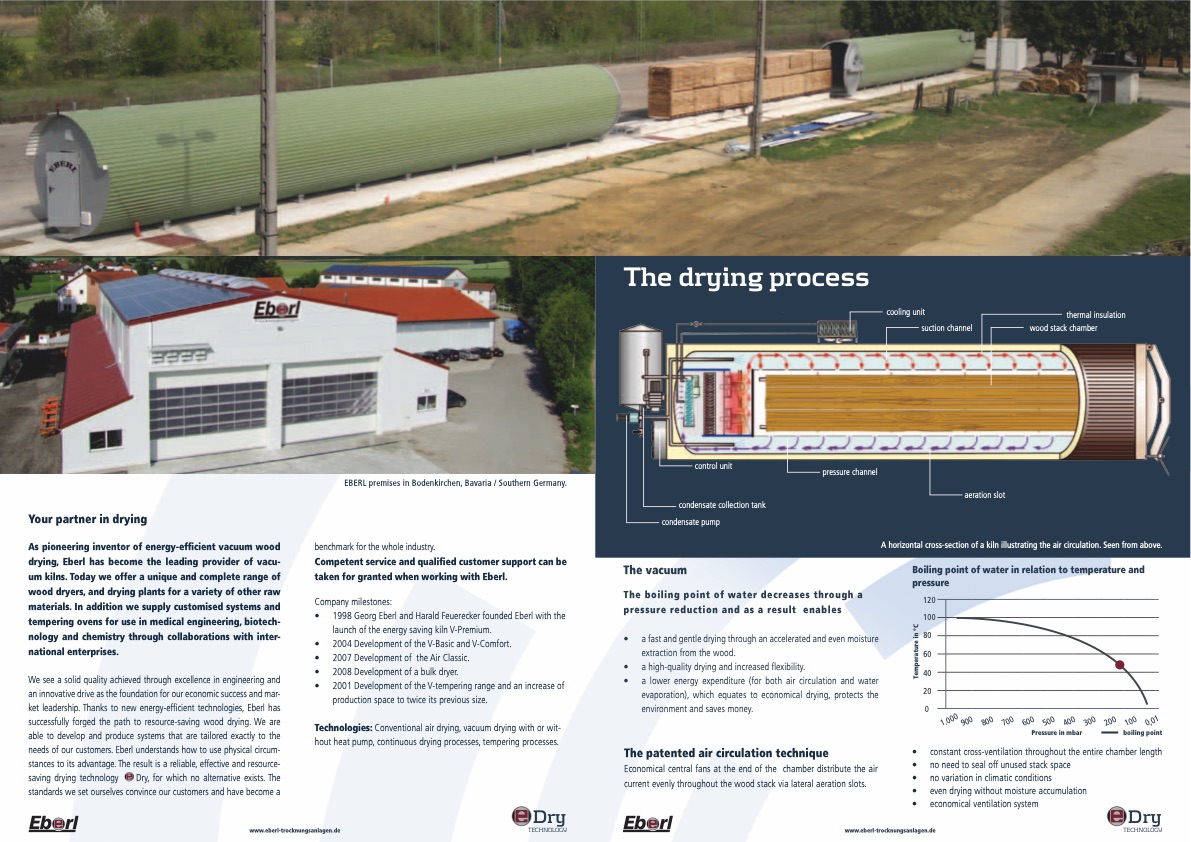

Your partner in drying As pioneering inventor of energy-efficient vacuum wood drying, Eberl has become the leading provider of vacu- um kilns. Today we offer a unique and complete range of wood dryers, and drying plants for a variety of other raw materials. In addition we supply customised systems and tempering ovens for use in medical engineering, biotech- nology and chemistry through collaborations with inter- national enterprises. We see a solid quality achieved through excellence in engineering and an innovative drive as the foundation for our economic success and mar- ket leadership. Thanks to new energy-efficient technologies, Eberl has successfully forged the path to resource-saving wood drying. We are able to develop and produce systems that are tailored exactly to the needs of our customers. EberlEuBndEeRrsLtands how to use physical circum- stances to its advantage. The result is a reliable, effective and resource- saving drying technology Dry, for which no alternative exists. The standards we set ourselves convince our customers and have become a EBERL premises in Bodenkirchen, Bavaria / Southern Germany. benchmark for the whole industry. Competent service and qualified customer support can be taken for granted when working with Eberl. Company milestones: • 1998 Georg Eberl and Harald Feuerecker founded Eberl with the launch of the energy saving kiln V-Premium. • 2004 Development of the V-Basic and V-Comfort. • 2007 Development of the Air Classic. • 2008 Development of a bulk dryer. • 2001 Development of the V-tempering range and an increase of production space to twice its previous size. Technologies: Conventional air drying, vacuum drying with or wit- hout heat pump, continuous drying processes, tempering processes. EBERL Dry The vacuum The boiling point of water decreases through a pressure reduction and as a result enables • a fast and gentle drying through an accelerated and even moisture extraction from the wood. • a high-quality drying and increased flexibility. • a lower energy expenditure (for both air circulation and water Boiling point of water in relation to temperature and pressure 120 100 80 60 40 20 evaporation), which equates to economical drying, protects the environment and saves money. 0 The patented air circulation technique Pressure in mbar boiling point DryBlue current evenly throughout the wood stack via lateral aeration slots. • • • no need to seal off unused stack space no variation in climatic conditions even drying without moisture accumulation economical ventilation system EBERL Dry www.eberl-trocknungsanlagen.de TECHNOLOGY www.eberl-trocknungsanlagen.de TECHNOLOGY • Economical central fans at the end of the chamber distribute the air • constant cross-ventilation throughout the entire chamber length The drying process cooling unit suction channel thermal insulation wood stack chamber control unit condensate collection tank condensate pump pressure channel aeration slot A horizontal cross-section of a kiln illustrating the air circulation. Seen from above. Temperature in °C 1.000 900 800 700 600 500 400 300 200 100 0,01PDF Image | The vacuum dry kiln

PDF Search Title:

The vacuum dry kilnOriginal File Name Searched:

ebe_vbasic_vcomfort_vpremium_2013_en.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |