PDF Publication Title:

Text from PDF Page: 001

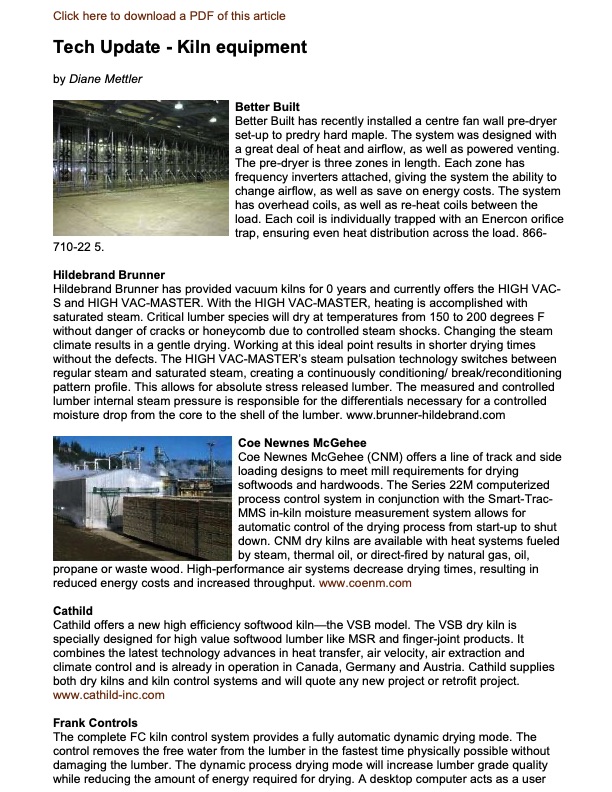

Click here to download a PDF of this article Tech Update - Kiln equipment by Diane Mettler 710-22 5. Hildebrand Brunner Better Built Better Built has recently installed a centre fan wall pre-dryer set-up to predry hard maple. The system was designed with a great deal of heat and airflow, as well as powered venting. The pre-dryer is three zones in length. Each zone has frequency inverters attached, giving the system the ability to change airflow, as well as save on energy costs. The system has overhead coils, as well as re-heat coils between the load. Each coil is individually trapped with an Enercon orifice trap, ensuring even heat distribution across the load. 866- Hildebrand Brunner has provided vacuum kilns for 0 years and currently offers the HIGH VAC- S and HIGH VAC-MASTER. With the HIGH VAC-MASTER, heating is accomplished with saturated steam. Critical lumber species will dry at temperatures from 150 to 200 degrees F without danger of cracks or honeycomb due to controlled steam shocks. Changing the steam climate results in a gentle drying. Working at this ideal point results in shorter drying times without the defects. The HIGH VAC-MASTER’s steam pulsation technology switches between regular steam and saturated steam, creating a continuously conditioning/ break/reconditioning pattern profile. This allows for absolute stress released lumber. The measured and controlled lumber internal steam pressure is responsible for the differentials necessary for a controlled moisture drop from the core to the shell of the lumber. www.brunner-hildebrand.com Coe Newnes McGehee Coe Newnes McGehee (CNM) offers a line of track and side loading designs to meet mill requirements for drying softwoods and hardwoods. The Series 22M computerized process control system in conjunction with the Smart-Trac- MMS in-kiln moisture measurement system allows for automatic control of the drying process from start-up to shut down. CNM dry kilns are available with heat systems fueled by steam, thermal oil, or direct-fired by natural gas, oil, propane or waste wood. High-performance air systems decrease drying times, resulting in reduced energy costs and increased throughput. www.coenm.com Cathild Cathild offers a new high efficiency softwood kiln—the VSB model. The VSB dry kiln is specially designed for high value softwood lumber like MSR and finger-joint products. It combines the latest technology advances in heat transfer, air velocity, air extraction and climate control and is already in operation in Canada, Germany and Austria. Cathild supplies both dry kilns and kiln control systems and will quote any new project or retrofit project. www.cathild-inc.com Frank Controls The complete FC kiln control system provides a fully automatic dynamic drying mode. The control removes the free water from the lumber in the fastest time physically possible without damaging the lumber. The dynamic process drying mode will increase lumber grade quality while reducing the amount of energy required for drying. A desktop computer acts as a userPDF Image | Tech Update - Kiln equipment

PDF Search Title:

Tech Update - Kiln equipmentOriginal File Name Searched:

TechUpdate.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |