PDF Publication Title:

Text from PDF Page: 002

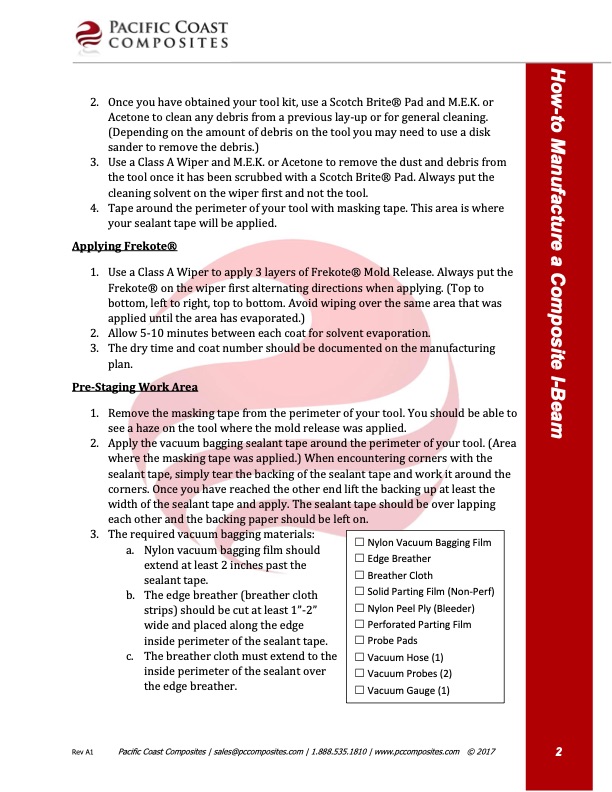

2. Once you have obtained your tool kit, use a Scotch Brite® Pad and M.E.K. or Acetone to clean any debris from a previous lay-up or for general cleaning. (Depending on the amount of debris on the tool you may need to use a disk sander to remove the debris.) 3. Use a Class A Wiper and M.E.K. or Acetone to remove the dust and debris from the tool once it has been scrubbed with a Scotch Brite® Pad. Always put the cleaning solvent on the wiper first and not the tool. 4. Tape around the perimeter of your tool with masking tape. This area is where your sealant tape will be applied. Applying Frekote® 1. Use a Class A Wiper to apply 3 layers of Frekote® Mold Release. Always put the Frekote® on the wiper first alternating directions when applying. (Top to bottom, left to right, top to bottom. Avoid wiping over the same area that was applied until the area has evaporated.) 2. Allow 5-10 minutes between each coat for solvent evaporation. 3. The dry time and coat number should be documented on the manufacturing plan. Pre-Staging Work Area 1. 2. 3. Remove the masking tape from the perimeter of your tool. You should be able to see a haze on the tool where the mold release was applied. Apply the vacuum bagging sealant tape around the perimeter of your tool. (Area where the masking tape was applied.) When encountering corners with the sealant tape, simply tear the backing of the sealant tape and work it around the corners. Once you have reached the other end lift the backing up at least the width of the sealant tape and apply. The sealant tape should be over lapping each other and the backing paper should be left on. The required vacuum bagging materials: a. Nylon vacuum bagging film should extend at least 2 inches past the sealant tape. b. The edge breather (breather cloth strips) should be cut at least 1”-2” wide and placed along the edge inside perimeter of the sealant tape. c. The breather cloth must extend to the inside perimeter of the sealant over the edge breather. ☐ Nylon Vacuum Bagging Film ☐ Edge Breather ☐ Breather Cloth ☐ Solid Parting Film (Non-Perf) ☐ Nylon Peel Ply (Bleeder) ☐ Perforated Parting Film ☐ Probe Pads ☐ Vacuum Hose (1) ☐ Vacuum Probes (2) ☐ Vacuum Gauge (1) Rev A1 Pacific Coast Composites | sales@pccomposites.com | 1.888.535.1810 | www.pccomposites.com © 2017 2 How-to Manufacture a Composite I-BeamPDF Image | Sandwich Panel

PDF Search Title:

Sandwich PanelOriginal File Name Searched:

How-to-Mfg-Composite-Sandwich-Panel.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |