PDF Publication Title:

Text from PDF Page: 003

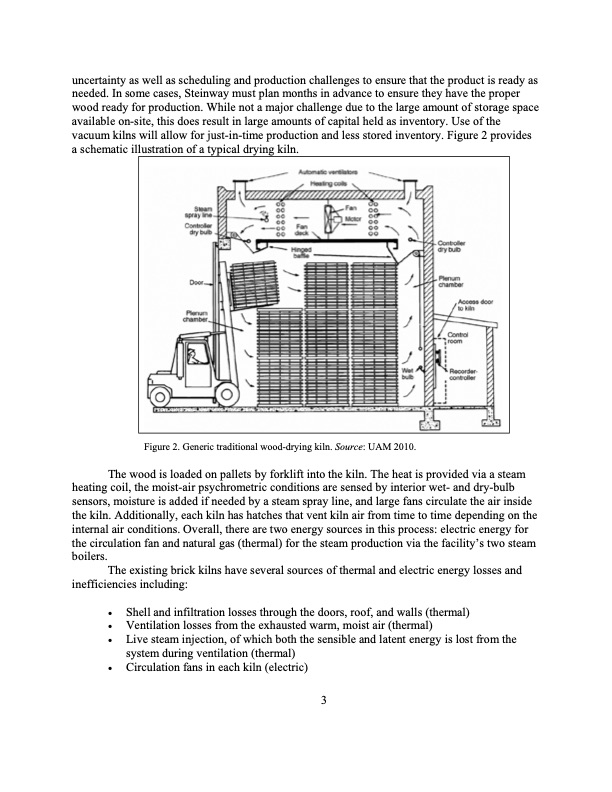

uncertainty as well as scheduling and production challenges to ensure that the product is ready as needed. In some cases, Steinway must plan months in advance to ensure they have the proper wood ready for production. While not a major challenge due to the large amount of storage space available on-site, this does result in large amounts of capital held as inventory. Use of the vacuum kilns will allow for just-in-time production and less stored inventory. Figure 2 provides a schematic illustration of a typical drying kiln. Figure 2. Generic traditional wood-drying kiln. Source: UAM 2010. The wood is loaded on pallets by forklift into the kiln. The heat is provided via a steam heating coil, the moist-air psychrometric conditions are sensed by interior wet- and dry-bulb sensors, moisture is added if needed by a steam spray line, and large fans circulate the air inside the kiln. Additionally, each kiln has hatches that vent kiln air from time to time depending on the internal air conditions. Overall, there are two energy sources in this process: electric energy for the circulation fan and natural gas (thermal) for the steam production via the facility’s two steam boilers. The existing brick kilns have several sources of thermal and electric energy losses and inefficiencies including: Shell and infiltration losses through the doors, roof, and walls (thermal) Ventilation losses from the exhausted warm, moist air (thermal) Live steam injection, of which both the sensible and latent energy is lost from the system during ventilation (thermal) Circulation fans in each kiln (electric) 3PDF Image | Quick-dry Partial Vacuum System

PDF Search Title:

Quick-dry Partial Vacuum SystemOriginal File Name Searched:

Kiln-Upgrade-Study-at-Steinway.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |