PDF Publication Title:

Text from PDF Page: 014

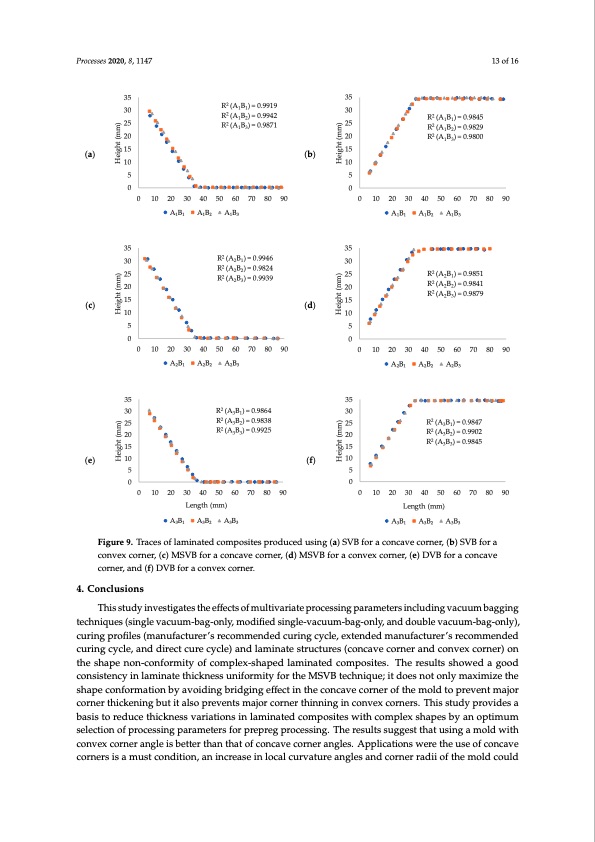

the relaxation of very low residual stresses accumulated at the corners to ultimately cause deviation. Whereas, the flat flange showed a remarkably close agreement in all bagging techniques and curing profiles. Furthermore, convex-cornered laminated composites showed excellent agreement in both inclined and flat flange regions; however, a slight decrease in the coefficient of correlation is subjected Ptroccesosersn2e0r20t,h8i,n1n14in7 g effect which causes data offset during observation. 13 of 16 (a) (b) 35 30 25 20 15 10 5 0 R2 (A1B1) = 0.9845 R2 (A1B2) = 0.9829 R2 (A1B3) = 0.9800 10 20 30 40 50 60 70 80 90 A1B1 A1B2 A1B3 0 35 30 25 20 15 10 5 0 R2 (A1B1) = 0.9919 R2 (A1B2) = 0.9942 R2 (A1B3) = 0.9871 10 20 30 40 50 60 70 80 90 A1B1 A1B2 A1B3 0 35 30 25 20 15 10 5 0 R2 (A2B1) = 0.9851 R2 (A2B2) = 0.9841 R2 (A2B3) = 0.9879 10 20 30 40 50 60 70 80 90 A2B1 A2B2 A2B3 0 35 30 25 20 15 10 5 0 R2 (A2B1) = 0.9946 R2 (A2B2) = 0.9824 R2 (A2B3) = 0.9939 10 20 30 40 50 60 70 80 90 A2B1 A2B2 A2B3 0 (c) (d) 35 30 25 20 15 10 5 0 R2 (A3B1) = 0.9847 R2 (A3B2) = 0.9902 R2 (A3B3) = 0.9845 10 20 30 40 50 60 70 80 90 Length (mm) A3B1 A3B2 A3B3 0 35 30 25 20 15 10 5 0 R2 (A3B1) = 0.9864 R2 (A3B2) = 0.9838 R2 (A3B3) = 0.9925 10 20 30 40 50 60 70 80 90 Length (mm) A3B1 A3B2 A3B3 0 (e) (f) Figure 9. Traces of laminated composites produced using (a) SVB for a concave corner, (b) SVB for a convex corner, (c) MSVB for a concave corner, (d) MSVB for a convex corner, (e) DVB for a concave corner, and (f) DVB for a convex corner. 4. Conclusions This study investigates the effects of multivariate processing parameters including vacuum bagging techniques (single vacuum-bag-only, modified single-vacuum-bag-only, and double vacuum-bag-only), curing profiles (manufacturer’s recommended curing cycle, extended manufacturer’s recommended curing cycle, and direct cure cycle) and laminate structures (concave corner and convex corner) on the shape non-conformity of complex-shaped laminated composites. The results showed a good consistency in laminate thickness uniformity for the MSVB technique; it does not only maximize the shape conformation by avoiding bridging effect in the concave corner of the mold to prevent major corner thickening but it also prevents major corner thinning in convex corners. This study provides a basis to reduce thickness variations in laminated composites with complex shapes by an optimum selection of processing parameters for prepreg processing. The results suggest that using a mold with convex corner angle is better than that of concave corner angles. Applications were the use of concave corners is a must condition, an increase in local curvature angles and corner radii of the mold could Height (mm) Height (mm) Height (mm) Height (mm) Height (mm) Height (mm)PDF Image | Processing Parameters for Vacuum-Bagging-Only Method on Shape

PDF Search Title:

Processing Parameters for Vacuum-Bagging-Only Method on ShapeOriginal File Name Searched:

processes-08-01147-2.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |