PDF Publication Title:

Text from PDF Page: 005

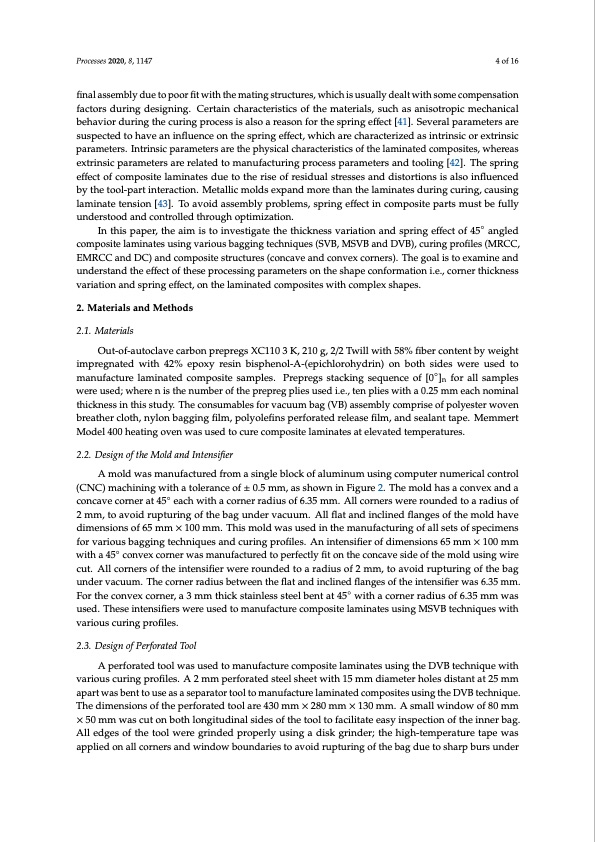

Processes 2020, 8, 1147 4 of 16 final assembly due to poor fit with the mating structures, which is usually dealt with some compensation factors during designing. Certain characteristics of the materials, such as anisotropic mechanical behavior during the curing process is also a reason for the spring effect [41]. Several parameters are suspected to have an influence on the spring effect, which are characterized as intrinsic or extrinsic parameters. Intrinsic parameters are the physical characteristics of the laminated composites, whereas extrinsic parameters are related to manufacturing process parameters and tooling [42]. The spring effect of composite laminates due to the rise of residual stresses and distortions is also influenced by the tool-part interaction. Metallic molds expand more than the laminates during curing, causing laminate tension [43]. To avoid assembly problems, spring effect in composite parts must be fully understood and controlled through optimization. In this paper, the aim is to investigate the thickness variation and spring effect of 45◦ angled composite laminates using various bagging techniques (SVB, MSVB and DVB), curing profiles (MRCC, EMRCC and DC) and composite structures (concave and convex corners). The goal is to examine and understand the effect of these processing parameters on the shape conformation i.e., corner thickness variation and spring effect, on the laminated composites with complex shapes. 2. Materials and Methods 2.1. Materials Out-of-autoclave carbon prepregs XC110 3 K, 210 g, 2/2 Twill with 58% fiber content by weight impregnated with 42% epoxy resin bisphenol-A-(epichlorohydrin) on both sides were used to manufacture laminated composite samples. Prepregs stacking sequence of [0◦]n for all samples were used; where n is the number of the prepreg plies used i.e., ten plies with a 0.25 mm each nominal thickness in this study. The consumables for vacuum bag (VB) assembly comprise of polyester woven breather cloth, nylon bagging film, polyolefins perforated release film, and sealant tape. Memmert Model 400 heating oven was used to cure composite laminates at elevated temperatures. 2.2. Design of the Mold and Intensifier A mold was manufactured from a single block of aluminum using computer numerical control (CNC) machining with a tolerance of ± 0.5 mm, as shown in Figure 2. The mold has a convex and a concave corner at 45◦ each with a corner radius of 6.35 mm. All corners were rounded to a radius of 2 mm, to avoid rupturing of the bag under vacuum. All flat and inclined flanges of the mold have dimensions of 65 mm × 100 mm. This mold was used in the manufacturing of all sets of specimens for various bagging techniques and curing profiles. An intensifier of dimensions 65 mm × 100 mm with a 45◦ convex corner was manufactured to perfectly fit on the concave side of the mold using wire cut. All corners of the intensifier were rounded to a radius of 2 mm, to avoid rupturing of the bag under vacuum. The corner radius between the flat and inclined flanges of the intensifier was 6.35 mm. For the convex corner, a 3 mm thick stainless steel bent at 45◦ with a corner radius of 6.35 mm was used. These intensifiers were used to manufacture composite laminates using MSVB techniques with various curing profiles. 2.3. Design of Perforated Tool A perforated tool was used to manufacture composite laminates using the DVB technique with various curing profiles. A 2 mm perforated steel sheet with 15 mm diameter holes distant at 25 mm apart was bent to use as a separator tool to manufacture laminated composites using the DVB technique. The dimensions of the perforated tool are 430 mm × 280 mm × 130 mm. A small window of 80 mm × 50 mm was cut on both longitudinal sides of the tool to facilitate easy inspection of the inner bag. All edges of the tool were grinded properly using a disk grinder; the high-temperature tape was applied on all corners and window boundaries to avoid rupturing of the bag due to sharp burs underPDF Image | Processing Parameters for Vacuum-Bagging-Only Method on Shape

PDF Search Title:

Processing Parameters for Vacuum-Bagging-Only Method on ShapeOriginal File Name Searched:

processes-08-01147-2.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |