PDF Publication Title:

Text from PDF Page: 042

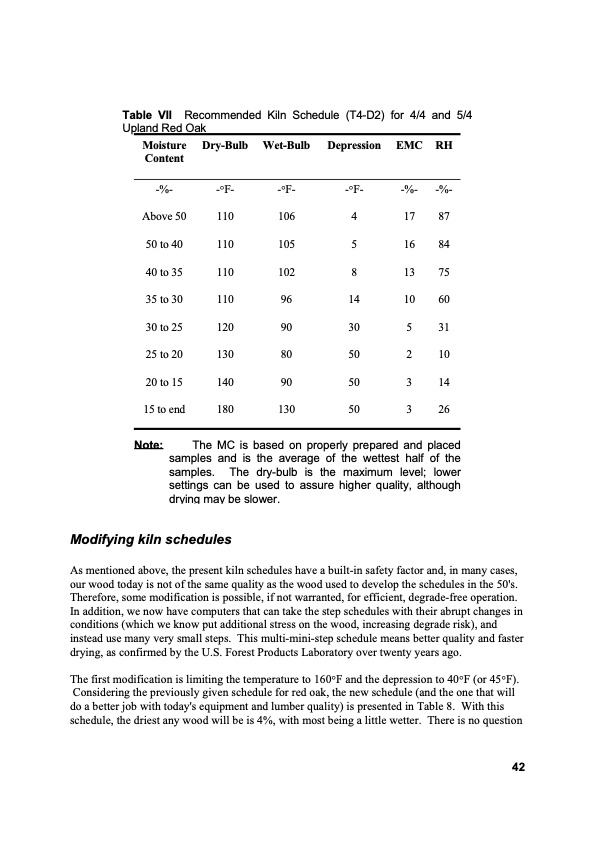

Table VII Recommended Kiln Schedule (T4-D2) for 4/4 and 5/4 Upland Red Oak Moisture Content -%- Above 50 50to40 40to35 35to30 30to25 25to20 20to15 15 to end Dry-Bulb Wet-Bulb -°F- -°F- 110 106 110 105 110 102 110 96 120 90 130 80 140 90 180 130 Depression EMC RH -°F- -%- -%- 4 17 87 5 16 84 8 13 75 14 10 60 30 5 31 50 2 10 50 3 14 50 3 26 Note: The MC is based on properly prepared and placed samples and is the average of the wettest half of the samples. The dry-bulb is the maximum level; lower settings can be used to assure higher quality, although drying may be slower. Modifying kiln schedules As mentioned above, the present kiln schedules have a built-in safety factor and, in many cases, our wood today is not of the same quality as the wood used to develop the schedules in the 50's. Therefore, some modification is possible, if not warranted, for efficient, degrade-free operation. In addition, we now have computers that can take the step schedules with their abrupt changes in conditions (which we know put additional stress on the wood, increasing degrade risk), and instead use many very small steps. This multi-mini-step schedule means better quality and faster drying, as confirmed by the U.S. Forest Products Laboratory over twenty years ago. The first modification is limiting the temperature to 160°F and the depression to 40°F (or 45°F). Considering the previously given schedule for red oak, the new schedule (and the one that will do a better job with today's equipment and lumber quality) is presented in Table 8. With this schedule, the driest any wood will be is 4%, with most being a little wetter. There is no question 42PDF Image | Principles and Practices of Drying Lumber

PDF Search Title:

Principles and Practices of Drying LumberOriginal File Name Searched:

DryingLumber.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |