PDF Publication Title:

Text from PDF Page: 036

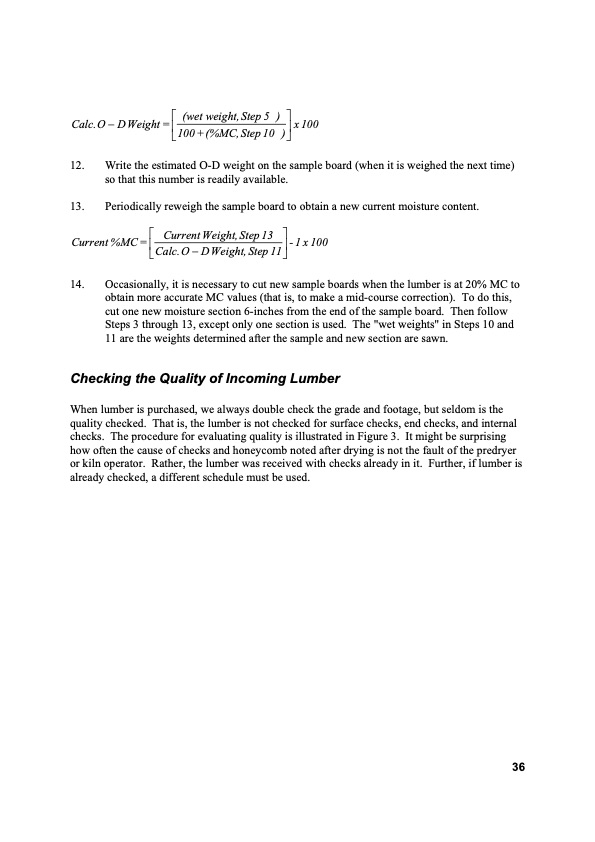

Calc.O−DWeight=⎡ (wetweight,Step5 ) ⎤x100 ⎢⎣100+(%MC,Step10 )⎥⎦ 12. Write the estimated O-D weight on the sample board (when it is weighed the next time) so that this number is readily available. 13. Periodically reweigh the sample board to obtain a new current moisture content. Current %MC = ⎡ Current Weight, Step 13 ⎤ - 1 x 100 ⎢⎣Calc.O − DWeight,Step 11⎥⎦ 14. Occasionally, it is necessary to cut new sample boards when the lumber is at 20% MC to obtain more accurate MC values (that is, to make a mid-course correction). To do this, cut one new moisture section 6-inches from the end of the sample board. Then follow Steps 3 through 13, except only one section is used. The "wet weights" in Steps 10 and 11 are the weights determined after the sample and new section are sawn. Checking the Quality of Incoming Lumber When lumber is purchased, we always double check the grade and footage, but seldom is the quality checked. That is, the lumber is not checked for surface checks, end checks, and internal checks. The procedure for evaluating quality is illustrated in Figure 3. It might be surprising how often the cause of checks and honeycomb noted after drying is not the fault of the predryer or kiln operator. Rather, the lumber was received with checks already in it. Further, if lumber is already checked, a different schedule must be used. 36PDF Image | Principles and Practices of Drying Lumber

PDF Search Title:

Principles and Practices of Drying LumberOriginal File Name Searched:

DryingLumber.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |