PDF Publication Title:

Text from PDF Page: 010

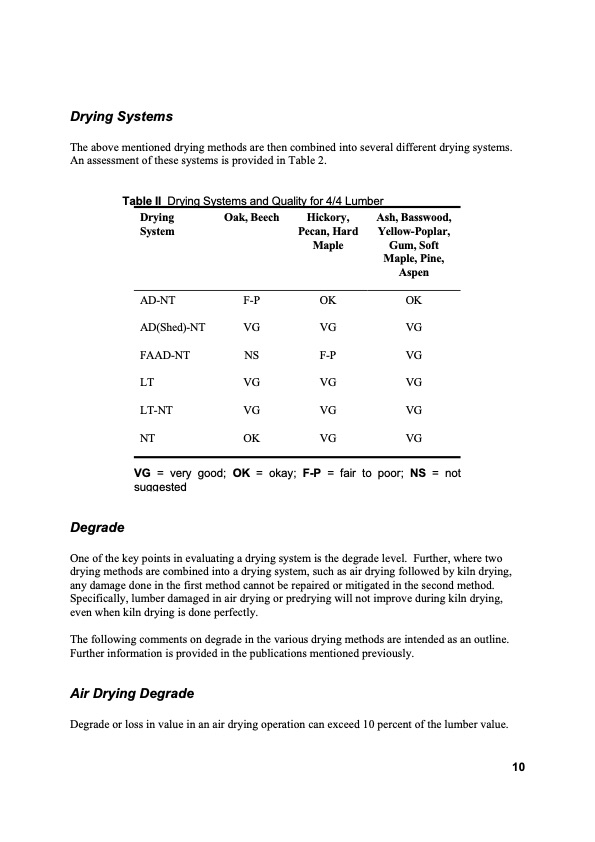

Drying Systems The above mentioned drying methods are then combined into several different drying systems. An assessment of these systems is provided in Table 2. Table II Drying Systems and Quality for 4/4 Lumber Drying Oak, Beech System AD-NT F-P AD(Shed)-NT VG FAAD-NT NS LT VG LT-NT VG NT OK Hickory, Pecan, Hard Maple OK VG F-P VG VG VG Ash, Basswood, Yellow-Poplar, Gum, Soft Maple, Pine, Aspen OK VG VG VG VG VG VG = very good; OK = okay; F-P = fair to poor; NS = not suggested Degrade One of the key points in evaluating a drying system is the degrade level. Further, where two drying methods are combined into a drying system, such as air drying followed by kiln drying, any damage done in the first method cannot be repaired or mitigated in the second method. Specifically, lumber damaged in air drying or predrying will not improve during kiln drying, even when kiln drying is done perfectly. The following comments on degrade in the various drying methods are intended as an outline. Further information is provided in the publications mentioned previously. Air Drying Degrade Degrade or loss in value in an air drying operation can exceed 10 percent of the lumber value. 10PDF Image | Principles and Practices of Drying Lumber

PDF Search Title:

Principles and Practices of Drying LumberOriginal File Name Searched:

DryingLumber.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |