PDF Publication Title:

Text from PDF Page: 006

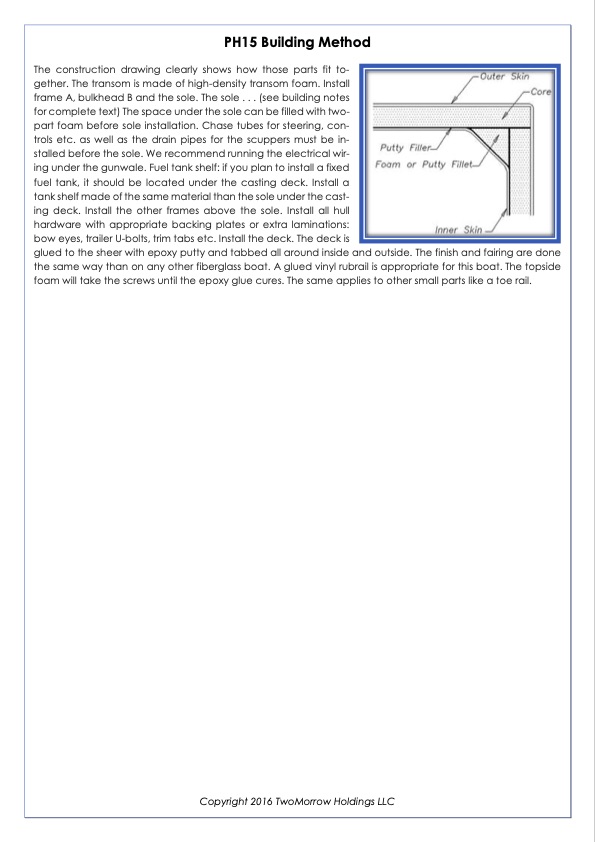

PH15 Building Method The construction drawing clearly shows how those parts fit to- gether. The transom is made of high-density transom foam. Install frame A, bulkhead B and the sole. The sole . . . (see building notes for complete text) The space under the sole can be filled with two- part foam before sole installation. Chase tubes for steering, con- trols etc. as well as the drain pipes for the scuppers must be in- stalled before the sole. We recommend running the electrical wir- ing under the gunwale. Fuel tank shelf: if you plan to install a fixed fuel tank, it should be located under the casting deck. Install a tank shelf made of the same material than the sole under the cast- ing deck. Install the other frames above the sole. Install all hull hardware with appropriate backing plates or extra laminations: bow eyes, trailer U-bolts, trim tabs etc. Install the deck. The deck is glued to the sheer with epoxy putty and tabbed all around inside and outside. The finish and fairing are done the same way than on any other fiberglass boat. A glued vinyl rubrail is appropriate for this boat. The topside foam will take the screws until the epoxy glue cures. The same applies to other small parts like a toe rail. Copyright 2016 TwoMorrow Holdings LLCPDF Image | PH15 Building Method Vacuum Bagging

PDF Search Title:

PH15 Building Method Vacuum BaggingOriginal File Name Searched:

ph15-building-method.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |