PDF Publication Title:

Text from PDF Page: 006

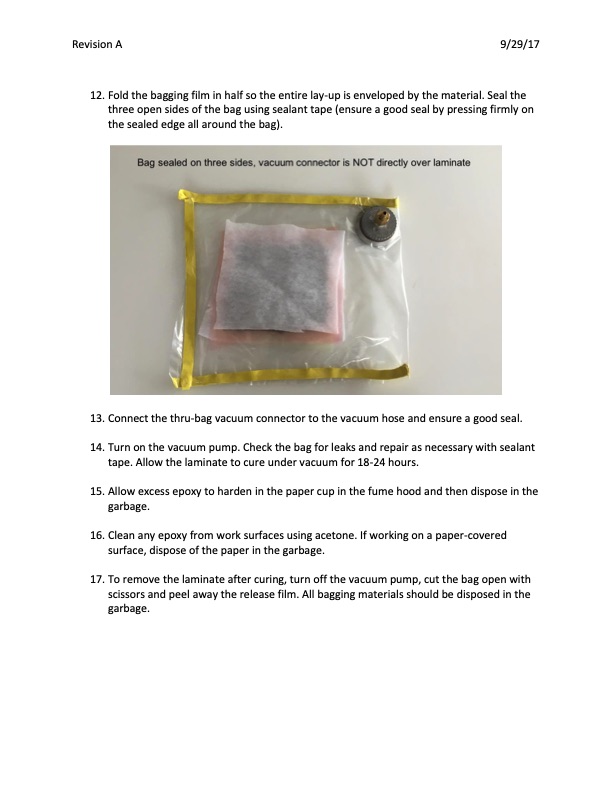

Revision A 9/29/17 12. Fold the bagging film in half so the entire lay-up is enveloped by the material. Seal the three open sides of the bag using sealant tape (ensure a good seal by pressing firmly on the sealed edge all around the bag). 13. Connect the thru-bag vacuum connector to the vacuum hose and ensure a good seal. 14. Turn on the vacuum pump. Check the bag for leaks and repair as necessary with sealant tape. Allow the laminate to cure under vacuum for 18-24 hours. 15. Allow excess epoxy to harden in the paper cup in the fume hood and then dispose in the garbage. 16. Clean any epoxy from work surfaces using acetone. If working on a paper-covered surface, dispose of the paper in the garbage. 17. To remove the laminate after curing, turn off the vacuum pump, cut the bag open with scissors and peel away the release film. All bagging materials should be disposed in the garbage.PDF Image | Laminate Vacuum Bagging Procedure

PDF Search Title:

Laminate Vacuum Bagging ProcedureOriginal File Name Searched:

Composite-Laminate-Vacuum-Bagging-Procedure.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |