PDF Publication Title:

Text from PDF Page: 064

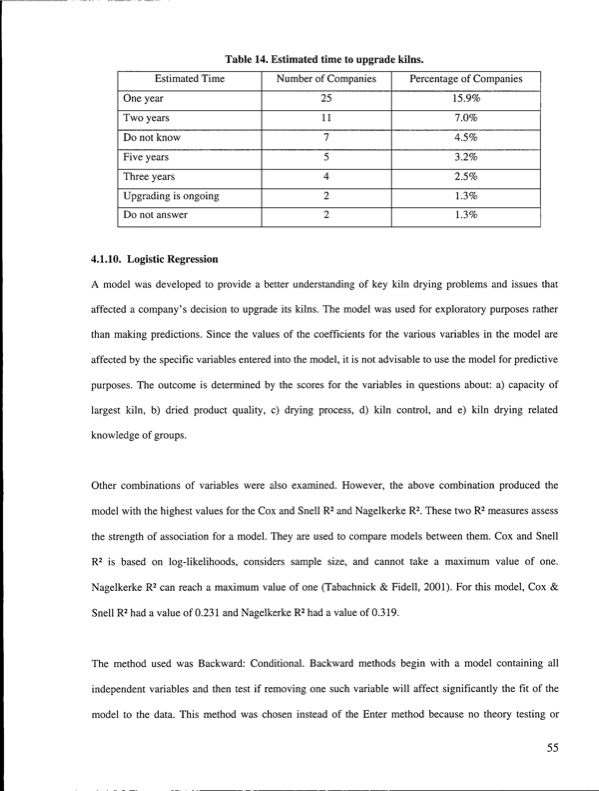

Estimated Time One year Two years Do not know Five years Three years Upgrading is ongoing Do not answer Number of Companies 25 11 7 5 4 2 2 Percentage of Companies 15.9% 7.0% 4.5% 3.2% 2.5% 1.3% 1.3% Table 14. Estimated time to upgrade kilns. 4.1.10. Logistic Regression A model was developed to provide a better understanding of key kiln drying problems and issues that affected a company's decision to upgrade its kilns. The model was used for exploratory purposes rather than making predictions. Since the values of the coefficients for the various variables in the model are affected by the specific variables entered into the model, it is not advisable to use the model for predictive purposes. The outcome is determined by the scores for the variables in questions about: a) capacity of largest kiln, b) dried product quality, c) drying process, d) kiln control, and e) kiln drying related knowledge of groups. Other combinations of variables were also examined. However, the above combination produced the model with the highest values for the Cox and Snell R 2 and Nagelkerke R 2 . These two R 2 measures assess the strength of association for a model. They are used to compare models between them. Cox and Snell R2 is based on log-likelihoods, considers sample size, and cannot take a maximum value of one. Nagelkerke R2 can reach a maximum value of one (Tabachnick & Fidell, 2001). For this model, Cox & Snell R 2 had a value of 0.231 and Nagelkerke R 2 had a value of 0.319. The method used was Backward: Conditional. Backward methods begin with a model containing all independent variables and then test if removing one such variable will affect significantly the fit of the model to the data. This method was chosen instead of the Enter method because no theory testing or 55PDF Image | KILN DRYING PROBLEMS AND ISSUES IN CANADA

PDF Search Title:

KILN DRYING PROBLEMS AND ISSUES IN CANADAOriginal File Name Searched:

ubc_2004-0049.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |