PDF Publication Title:

Text from PDF Page: 151

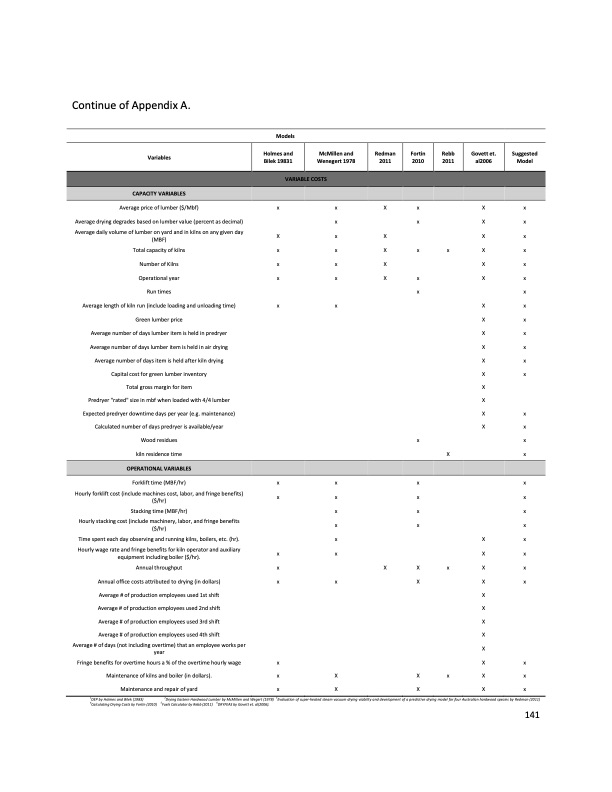

Continue of Appendix A. Variables Average price of lumber ($/Mbf) Average drying degrades based on lumber value (percent as decimal) Average daily volume of lumber on yard and in kilns on any given day (MBF) Total capacity of kilns Number of Kilns Operational year Run times Average length of kiln run (include loading and unloading time) Green lumber price Average number of days lumber item is held in predryer Average number of days lumber item is held in air drying Average number of days item is held after kiln drying Capital cost for green lumber inventory Total gross margin for item Predryer "rated" size in mbf when loaded with 4/4 lumber Expected predryer downtime days per year (e.g. maintenance) Calculated number of days predryer is available/year Wood residues kiln residence time Forklift time (MBF/hr) Hourly forklift cost (include machines cost, labor, and fringe benefits) ($/hr) Stacking time (MBF/hr) Hourly stacking cost (include machinery, labor, and fringe benefits ($/hr) Time spent each day observing and running kilns, boilers, etc. (hr). Hourly wage rate and fringe benefits for kiln operator and auxiliary equipment including boiler ($/hr). Models Holmes and McMillen and Redman Fortin Rebb Govett et. Suggested Bilek 19831 Wenegert 1978 2011 2010 2011 al2006 Model xxXxXx x x X x XxXXx Annual throughput x Annual office costs attributed to drying (in dollars) x x Average # of production employees used 1st shift Average # of production employees used 2nd shift Average # of production employees used 3rd shift Average # of production employees used 4th shift Average # of days (not including overtime) that an employee works per year Fringe benefits for overtime hours a % of the overtime hourly wage x Maintenance of kilns and boiler (in dollars). x X Maintenance and repair of yard x X X Xx X x X X x X X X X X X x Xx X x X X x VARIABLE COSTS CAPACITY VARIABLES x x X x x x X x x X x x X x X x X x x X x X x X x X x X x X x X X X x X x x x x x x x x xxxx x x x xxx x X x xxXx x x X OPERATIONAL VARIABLES x 123 DEP by Holmes and Bilek (1983) Drying Eastern Hardwood Lumber by McMillen and Wegert (1978) Evaluation of super-heated steam vacuum drying viability and development of a predictive drying model for four Australian hardwood species by Redman (2011) 456 Calculating Drying Costs by Fortin (2010) Fuels Calculator by Rebb (2011) DRYFEAS by Govett et. al(2006). 141PDF Image | Impact of Vacuum-Drying on Efficiency of Hardwood Products

PDF Search Title:

Impact of Vacuum-Drying on Efficiency of Hardwood ProductsOriginal File Name Searched:

Brenes_Angulo_OM_T_2014.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |