PDF Publication Title:

Text from PDF Page: 119

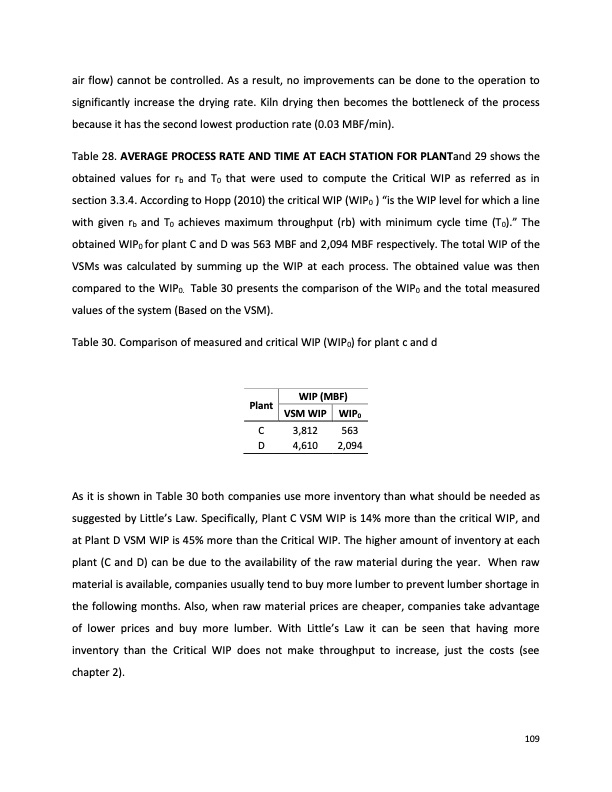

air flow) cannot be controlled. As a result, no improvements can be done to the operation to significantly increase the drying rate. Kiln drying then becomes the bottleneck of the process because it has the second lowest production rate (0.03 MBF/min). Table 28. AVERAGE PROCESS RATE AND TIME AT EACH STATION FOR PLANTand 29 shows the obtained values for rb and T0 that were used to compute the Critical WIP as referred as in section 3.3.4. According to Hopp (2010) the critical WIP (WIP0 ) “is the WIP level for which a line with given rb and T0 achieves maximum throughput (rb) with minimum cycle time (T0).” The obtained WIP0 for plant C and D was 563 MBF and 2,094 MBF respectively. The total WIP of the VSMs was calculated by summing up the WIP at each process. The obtained value was then compared to the WIP0. Table 30 presents the comparison of the WIP0 and the total measured values of the system (Based on the VSM). Table 30. Comparison of measured and critical WIP (WIP0) for plant c and d WIP (MBF) VSM WIP WIP0 C 3,812 563 D 4,610 2,094 As it is shown in Table 30 both companies use more inventory than what should be needed as suggested by Little’s Law. Specifically, Plant C VSM WIP is 14% more than the critical WIP, and at Plant D VSM WIP is 45% more than the Critical WIP. The higher amount of inventory at each plant (C and D) can be due to the availability of the raw material during the year. When raw material is available, companies usually tend to buy more lumber to prevent lumber shortage in the following months. Also, when raw material prices are cheaper, companies take advantage of lower prices and buy more lumber. With Little’s Law it can be seen that having more inventory than the Critical WIP does not make throughput to increase, just the costs (see chapter 2). Plant 109PDF Image | Impact of Vacuum-Drying on Efficiency of Hardwood Products

PDF Search Title:

Impact of Vacuum-Drying on Efficiency of Hardwood ProductsOriginal File Name Searched:

Brenes_Angulo_OM_T_2014.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |