PDF Publication Title:

Text from PDF Page: 109

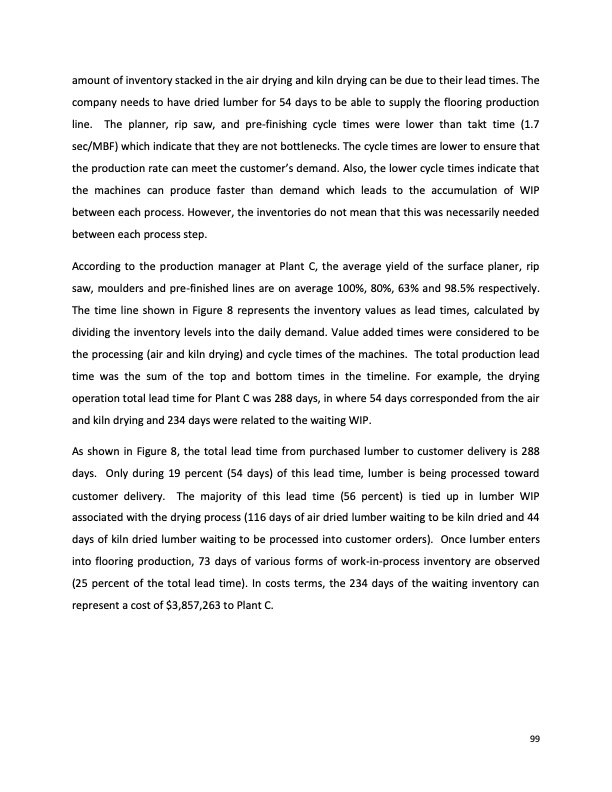

amount of inventory stacked in the air drying and kiln drying can be due to their lead times. The company needs to have dried lumber for 54 days to be able to supply the flooring production line. The planner, rip saw, and pre-finishing cycle times were lower than takt time (1.7 sec/MBF) which indicate that they are not bottlenecks. The cycle times are lower to ensure that the production rate can meet the customer’s demand. Also, the lower cycle times indicate that the machines can produce faster than demand which leads to the accumulation of WIP between each process. However, the inventories do not mean that this was necessarily needed between each process step. According to the production manager at Plant C, the average yield of the surface planer, rip saw, moulders and pre-finished lines are on average 100%, 80%, 63% and 98.5% respectively. The time line shown in Figure 8 represents the inventory values as lead times, calculated by dividing the inventory levels into the daily demand. Value added times were considered to be the processing (air and kiln drying) and cycle times of the machines. The total production lead time was the sum of the top and bottom times in the timeline. For example, the drying operation total lead time for Plant C was 288 days, in where 54 days corresponded from the air and kiln drying and 234 days were related to the waiting WIP. As shown in Figure 8, the total lead time from purchased lumber to customer delivery is 288 days. Only during 19 percent (54 days) of this lead time, lumber is being processed toward customer delivery. The majority of this lead time (56 percent) is tied up in lumber WIP associated with the drying process (116 days of air dried lumber waiting to be kiln dried and 44 days of kiln dried lumber waiting to be processed into customer orders). Once lumber enters into flooring production, 73 days of various forms of work-in-process inventory are observed (25 percent of the total lead time). In costs terms, the 234 days of the waiting inventory can represent a cost of $3,857,263 to Plant C. 99PDF Image | Impact of Vacuum-Drying on Efficiency of Hardwood Products

PDF Search Title:

Impact of Vacuum-Drying on Efficiency of Hardwood ProductsOriginal File Name Searched:

Brenes_Angulo_OM_T_2014.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |