PDF Publication Title:

Text from PDF Page: 103

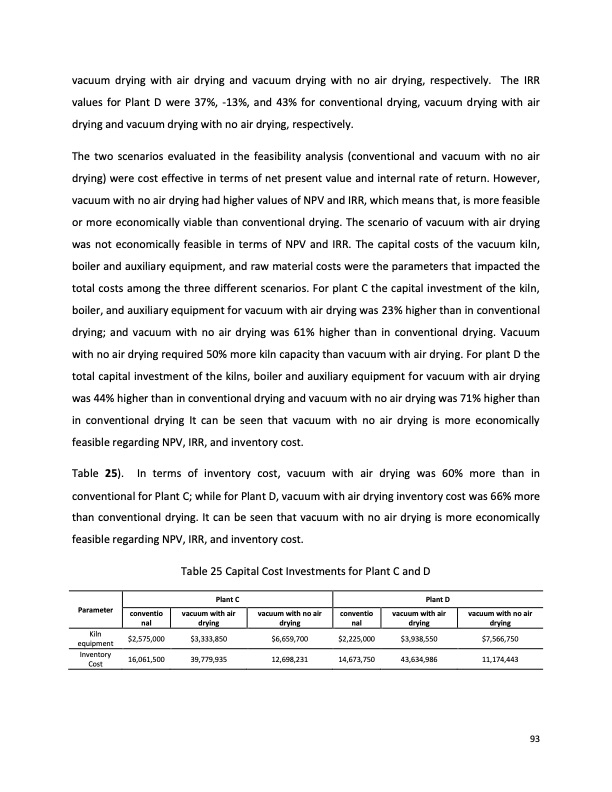

vacuum drying with air drying and vacuum drying with no air drying, respectively. The IRR values for Plant D were 37%, -13%, and 43% for conventional drying, vacuum drying with air drying and vacuum drying with no air drying, respectively. The two scenarios evaluated in the feasibility analysis (conventional and vacuum with no air drying) were cost effective in terms of net present value and internal rate of return. However, vacuum with no air drying had higher values of NPV and IRR, which means that, is more feasible or more economically viable than conventional drying. The scenario of vacuum with air drying was not economically feasible in terms of NPV and IRR. The capital costs of the vacuum kiln, boiler and auxiliary equipment, and raw material costs were the parameters that impacted the total costs among the three different scenarios. For plant C the capital investment of the kiln, boiler, and auxiliary equipment for vacuum with air drying was 23% higher than in conventional drying; and vacuum with no air drying was 61% higher than in conventional drying. Vacuum with no air drying required 50% more kiln capacity than vacuum with air drying. For plant D the total capital investment of the kilns, boiler and auxiliary equipment for vacuum with air drying was 44% higher than in conventional drying and vacuum with no air drying was 71% higher than in conventional drying It can be seen that vacuum with no air drying is more economically feasible regarding NPV, IRR, and inventory cost. Table 25). In terms of inventory cost, vacuum with air drying was 60% more than in conventional for Plant C; while for Plant D, vacuum with air drying inventory cost was 66% more than conventional drying. It can be seen that vacuum with no air drying is more economically feasible regarding NPV, IRR, and inventory cost. Table 25 Capital Cost Investments for Plant C and D Parameter Kiln equipment Inventory Cost conventio nal $2,575,000 16,061,500 Plant C vacuum with air drying $3,333,850 39,779,935 vacuum with no air drying $6,659,700 12,698,231 conventio nal $2,225,000 14,673,750 Plant D vacuum with air drying $3,938,550 43,634,986 vacuum with no air drying $7,566,750 11,174,443 93PDF Image | Impact of Vacuum-Drying on Efficiency of Hardwood Products

PDF Search Title:

Impact of Vacuum-Drying on Efficiency of Hardwood ProductsOriginal File Name Searched:

Brenes_Angulo_OM_T_2014.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |