PDF Publication Title:

Text from PDF Page: 067

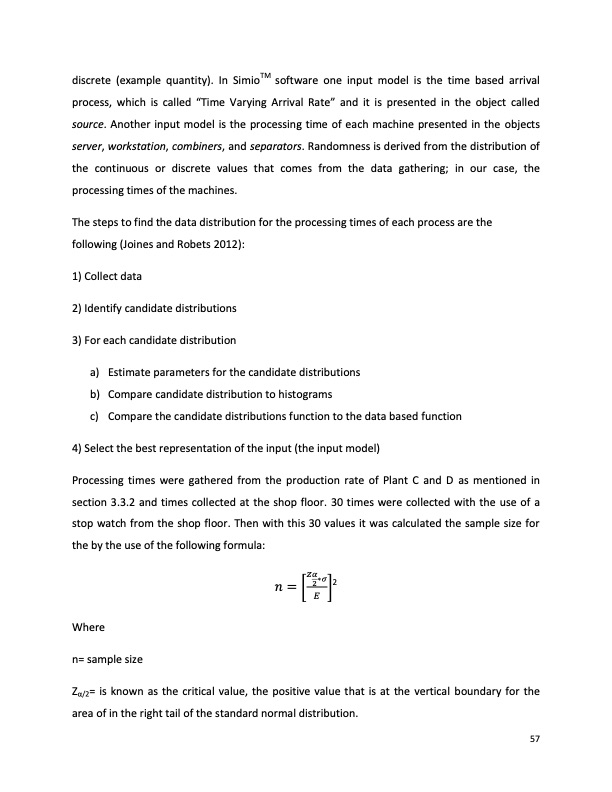

discrete (example quantity). In SimioTM software one input model is the time based arrival process, which is called “Time Varying Arrival Rate” and it is presented in the object called source. Another input model is the processing time of each machine presented in the objects server, workstation, combiners, and separators. Randomness is derived from the distribution of the continuous or discrete values that comes from the data gathering; in our case, the processing times of the machines. The steps to find the data distribution for the processing times of each process are the following (Joines and Robets 2012): 1) Collect data 2) Identify candidate distributions 3) For each candidate distribution a) Estimate parameters for the candidate distributions b) Compare candidate distribution to histograms c) Compare the candidate distributions function to the data based function 4) Select the best representation of the input (the input model) Processing times were gathered from the production rate of Plant C and D as mentioned in section 3.3.2 and times collected at the shop floor. 30 times were collected with the use of a stop watch from the shop floor. Then with this 30 values it was calculated the sample size for the by the use of the following formula: [ ]2 Where n= sample size Zα/2= is known as the critical value, the positive value that is at the vertical boundary for the area of in the right tail of the standard normal distribution. 57PDF Image | Impact of Vacuum-Drying on Efficiency of Hardwood Products

PDF Search Title:

Impact of Vacuum-Drying on Efficiency of Hardwood ProductsOriginal File Name Searched:

Brenes_Angulo_OM_T_2014.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |