PDF Publication Title:

Text from PDF Page: 114

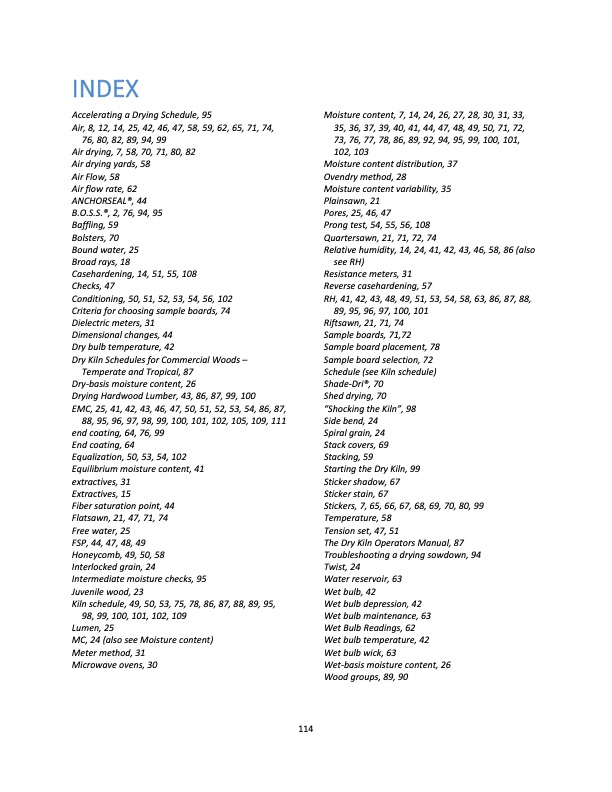

INDEX Accelerating a Drying Schedule, 95 Air, 8, 12, 14, 25, 42, 46, 47, 58, 59, 62, 65, 71, 74, 76, 80, 82, 89, 94, 99 Air drying, 7, 58, 70, 71, 80, 82 Air drying yards, 58 Air Flow, 58 Air flow rate, 62 ANCHORSEAL®, 44 B.O.S.S.®, 2, 76, 94, 95 Baffling, 59 Bolsters, 70 Bound water, 25 Broad rays, 18 Casehardening, 14, 51, 55, 108 Checks, 47 Conditioning, 50, 51, 52, 53, 54, 56, 102 Criteria for choosing sample boards, 74 Dielectric meters, 31 Dimensional changes, 44 Dry bulb temperature, 42 Dry Kiln Schedules for Commercial Woods – Temperate and Tropical, 87 Dry-basis moisture content, 26 Drying Hardwood Lumber, 43, 86, 87, 99, 100 EMC, 25, 41, 42, 43, 46, 47, 50, 51, 52, 53, 54, 86, 87, 88, 95, 96, 97, 98, 99, 100, 101, 102, 105, 109, 111 end coating, 64, 76, 99 End coating, 64 Equalization, 50, 53, 54, 102 Equilibrium moisture content, 41 extractives, 31 Extractives, 15 Fiber saturation point, 44 Flatsawn, 21, 47, 71, 74 Free water, 25 FSP, 44, 47, 48, 49 Honeycomb, 49, 50, 58 Interlocked grain, 24 Intermediate moisture checks, 95 Juvenile wood, 23 Kiln schedule, 49, 50, 53, 75, 78, 86, 87, 88, 89, 95, 98, 99, 100, 101, 102, 109 Lumen, 25 MC, 24 (also see Moisture content) Meter method, 31 Microwave ovens, 30 Moisture content, 7, 14, 24, 26, 27, 28, 30, 31, 33, 35, 36, 37, 39, 40, 41, 44, 47, 48, 49, 50, 71, 72, 73, 76, 77, 78, 86, 89, 92, 94, 95, 99, 100, 101, 102, 103 Moisture content distribution, 37 Ovendry method, 28 Moisture content variability, 35 Plainsawn, 21 Pores, 25, 46, 47 Prong test, 54, 55, 56, 108 Quartersawn, 21, 71, 72, 74 Relative humidity, 14, 24, 41, 42, 43, 46, 58, 86 (also see RH) Resistance meters, 31 Reverse casehardening, 57 RH, 41, 42, 43, 48, 49, 51, 53, 54, 58, 63, 86, 87, 88, 89, 95, 96, 97, 100, 101 Riftsawn, 21, 71, 74 Sample boards, 71,72 Sample board placement, 78 Sample board selection, 72 Schedule (see Kiln schedule) Shade-Dri®, 70 Shed drying, 70 “Shocking the Kiln”, 98 Side bend, 24 Spiral grain, 24 Stack covers, 69 Stacking, 59 Starting the Dry Kiln, 99 Sticker shadow, 67 Sticker stain, 67 Stickers, 7, 65, 66, 67, 68, 69, 70, 80, 99 Temperature, 58 Tension set, 47, 51 The Dry Kiln Operators Manual, 87 Troubleshooting a drying sowdown, 94 Twist, 24 Water reservoir, 63 Wet bulb, 42 Wet bulb depression, 42 Wet bulb maintenance, 63 Wet Bulb Readings, 62 Wet bulb temperature, 42 Wet bulb wick, 63 Wet-basis moisture content, 26 Wood groups, 89, 90 114PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |