PDF Publication Title:

Text from PDF Page: 086

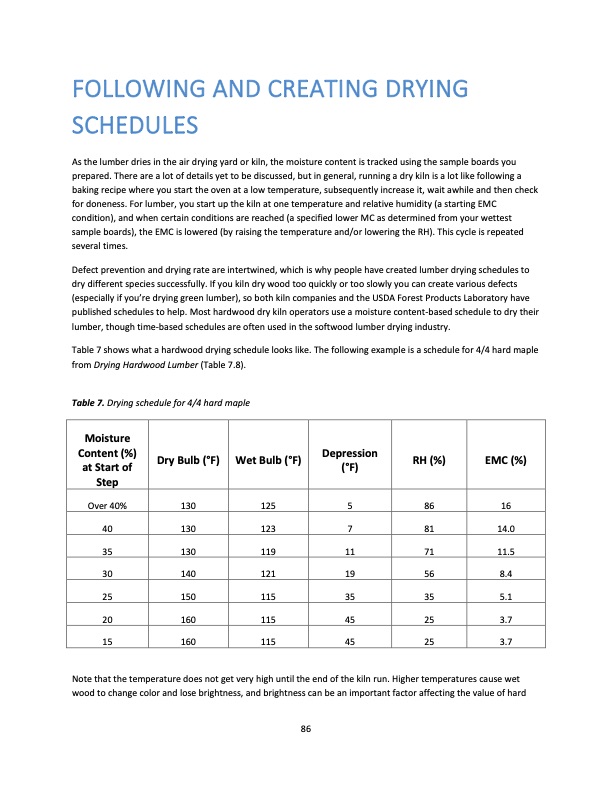

FOLLOWING AND CREATING DRYING SCHEDULES As the lumber dries in the air drying yard or kiln, the moisture content is tracked using the sample boards you prepared. There are a lot of details yet to be discussed, but in general, running a dry kiln is a lot like following a baking recipe where you start the oven at a low temperature, subsequently increase it, wait awhile and then check for doneness. For lumber, you start up the kiln at one temperature and relative humidity (a starting EMC condition), and when certain conditions are reached (a specified lower MC as determined from your wettest sample boards), the EMC is lowered (by raising the temperature and/or lowering the RH). This cycle is repeated several times. Defect prevention and drying rate are intertwined, which is why people have created lumber drying schedules to dry different species successfully. If you kiln dry wood too quickly or too slowly you can create various defects (especially if you’re drying green lumber), so both kiln companies and the USDA Forest Products Laboratory have published schedules to help. Most hardwood dry kiln operators use a moisture content-based schedule to dry their lumber, though time-based schedules are often used in the softwood lumber drying industry. Table 7 shows what a hardwood drying schedule looks like. The following example is a schedule for 4/4 hard maple from Drying Hardwood Lumber (Table 7.8). Table 7. Drying schedule for 4/4 hard maple Moisture Content (%) at Start of Step Dry Bulb (°F) Wet Bulb (°F) Depression (°F) RH (%) EMC (%) Over 40% 40 35 30 25 20 15 130 125 130 123 130 119 140 121 150 115 160 115 160 115 5 86 16 7 81 14.0 11 71 11.5 19 56 8.4 35 35 5.1 45 25 3.7 45 25 3.7 Note that the temperature does not get very high until the end of the kiln run. Higher temperatures cause wet wood to change color and lose brightness, and brightness can be an important factor affecting the value of hard 86PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |